I’d like to propose we build 5 tables per the attached sketch. I suggest 2 with steel tops for the metal shop, and 3 with MDF tops for general Hive13 use (assembly, workspace, etc.; 1 in Fab Lab, 2 in main area).

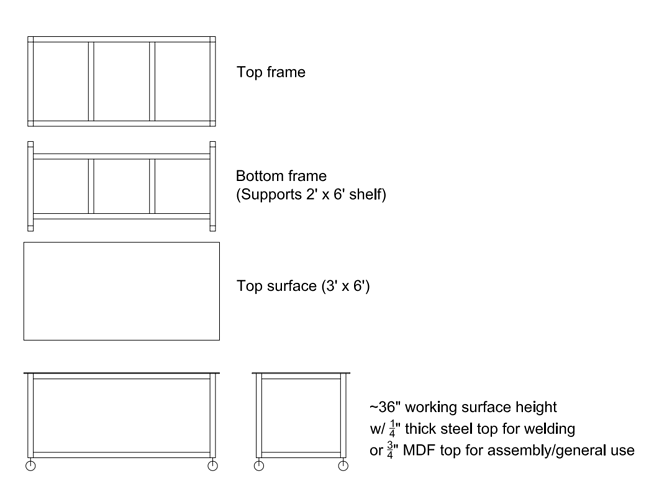

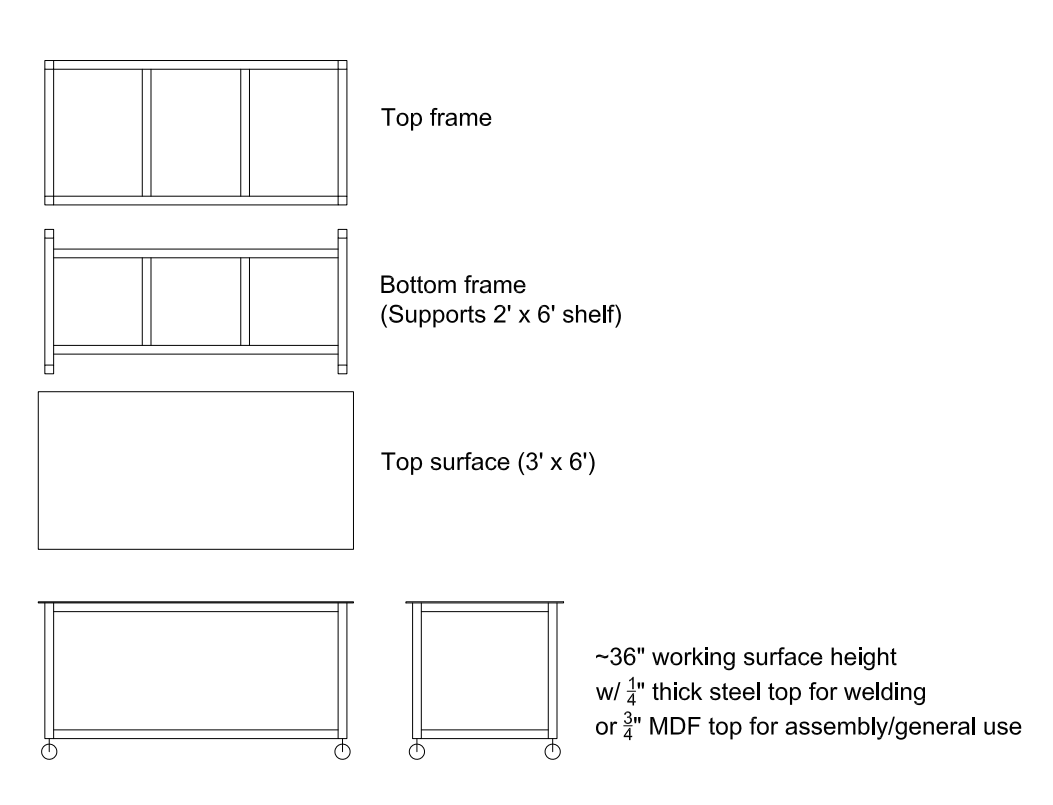

Construction will be welded 2" x 2" steel tube frame. Casters will be swivel machine casters with leveling stops so the tables can be wheeled around and then leveled on feet for stability while working.

These will be heavy, sturdy tables able to withstand significant abuse, and the tops will be replaceable to account for wear and tear. While 2" steel tube is more expensive than some other constructions, having a sturdy stable work surface is WELL worth the increase in cost. I have not been able to identify a comparable pre-built work table.

Per request, one of the welding tables will be ~28" sitting work height for more precise TIG work instead of the 36" counter height I propose for the others and will have the shelf shifted all the way to the back so the table can stay against the wall to allow space for a chair.

Total cost I priced out for all five tables would be $1298 (cost breakdown below). To account for any odds and ends, in process improvements, shipping, etc. I propose the vote be for $1600.

qty length extended length

top sides 2 65 130 in

top ends 2 29 58 in

top supports 2 29 58 in

legs 4 31 124 in

bottom ends 2 29 58 in

bottom supports 2 20 40 in

bottom sides 2 65 130 in

598 in

49.833333 ft

price price weight weight

MDF Steel lb. lb.

Steel Tube $ 97.90 $ 97.90 130 130

Top $ 20.72 $ 159.75 54 184

MDF Shelf $ 10.36 $ 10.36 36 36

Casters $75.00 $ 75.00 9 9

Total $ 203.98 $ 343.01 229 359

Price Qty Total

Steel Top $ 343.01 2 $ 686.02

MDF Top $ 203.98 3 $ 611.94

Total $ 1,297.96

The in-person voting for this proposal will be at the 12/18/2018 meeting. If the vote is passed, I would expect to have the tables built by the end of January.

Thanks,

Kevin McLeod

Woodworking Warden