All,

First – all parts for Weller iron repair should arrive tomorrow.

I am proposing a vote for $1,459.32 to upgrade our electronics lab. Yes, there is a spreadsheet at the bottom, and yes, Greg will make fun of me for being “over-kill” and “compulsive” at the meeting. However, this is detailed work, so it is needed.

I realize this is a lot of money, especially if you’re used to spending $10 here and there on arduinos, and using a $40 soldering iron.I am estimating on the high-side and anticipate coming in under budget. Still, though, we need to commit to having a functioning electronics lab with comparable tooling to our other facilities. I am including a link and itemized estimate below.

As you may know, most of the equipment we have is donated equipment (mostly Dave, John, and myself, and Dave {lot’s of stuff from dave}). We are really behind in electronics area, and losing ground as things break (most breakage has just been simply due too the age of the equipment).

Proposal includes:

Bench upgrades:

Pro Soldering Iron

Fume extraction / venting

Needed bench equipment

Needed SAFETY equipment

PCB Production:

Photo etching setup (this is what I use)

Setting up shapeoko as a PCB mill (it can do it down to 0604, even 04)

SMD Reflow:

Reflow toaster needs an overhaul

Various stocked parts:

Asst wire 18-24ga

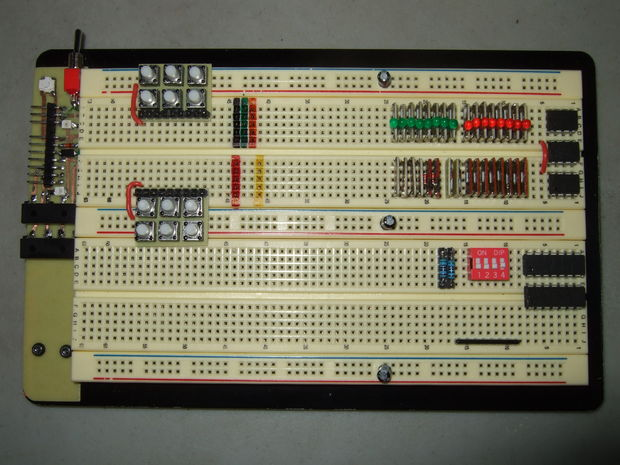

Common parts: buttons, micros, pots, trimmers, R, C, L

Replacement of some expendables

Storage solutions (parts drawers, etc)

More here in itemized spreadsheet:

https://docs.google.com/spreadsheets/d/1yIgh209Li_DrxsmB1-WPnB_XZiu790BEPY-r4RC8VzE/edit?usp=sharing

The hive needs to own electronics tools. If Dave, John, and I reclaimed our stuff, we’d have almost no electronics tools!

We need pro-quality tools. That’s why we’re here, right?

We need to use & teach in this area.

Individually, all these things are cheap, but small stuff adds up. We need a lot. After this, we can keep ahead of expendables and breakage with warden budget for a while.

Lorin