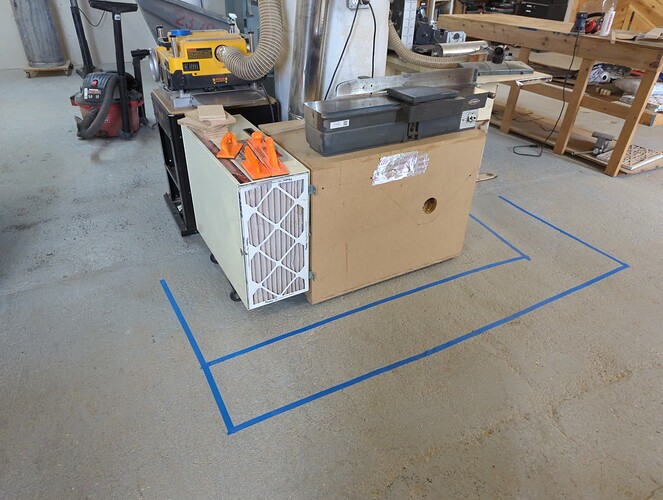

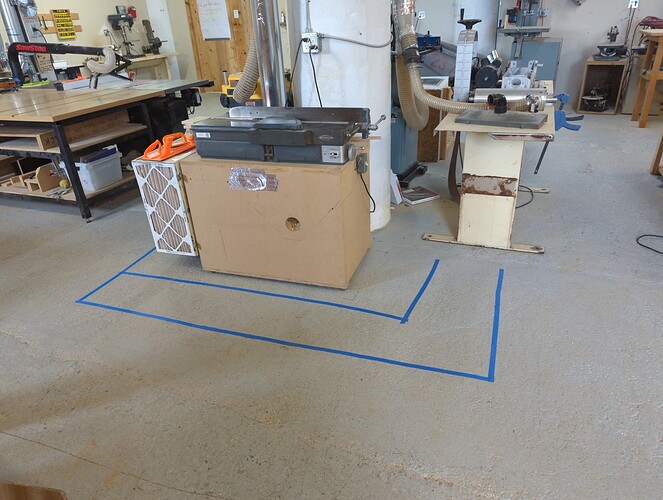

I’d like to open a discussion about the woodshop and jointers. Today I attempted to our jointer for the first time since well before the move. As it stands our jointer is virtually useless. I suspect the knives are dull. Even with brand spanking new sharp knives that jointer would fall someplace on the continuum of inadequate to useless. We have a fantastic table saw, a really nice lathe, and the rest of the equipment is more than adequate. We do not have a complete woodshop without a usable jointer.

As an aside, in my shop the jointer is either tied for the most used machine with the table saw or is the second most used machine. I’d rather do without my miter saw, a nice bandsaw, or maybe even my router table than do without a usable jointer.

There are several long term solutions that I see:

As a short term, and very cumbersome solution, those who need a jointer can arrange with me to come up to the 4th floor and use my jointer.

Replace the knives on our current jointer. This can be easily accomplished within the wardens budget but leaves us with, at best, an inadequate jointer.

An acceptable but less than great jointer like my Ridge that was at the Hive for a while following the move. The budget for this would be $900 – 1,200.

Get a great jointer that would be an equal to the table saw. 70+ inch bed, 8” capacity, with spiral cutter heads. Budget for this would start around $2,700 and go up to whatever ridiculous amount of money you want to spend.

Buy a used jointer with potential problems that would require additional $ and time to fix.

???

I realize that we have a huge upcoming expense in building out the dungeon. I am not proposing anything at this point. I just want to gauge interest, get input from others, and maybe someone else will have a solution that I haven’t come up with. However, seeing that the woodshop is one of our most used spaces and I don’t believe we can claim to have a complete woodshop without an acceptable jointer something has to be done.

Please, share thoughts. Share suggestions. Tell me I’m nuts. Whatever. Let’s talk.

A really nice, new jointer is well within our purchasing power, I would support it (despite having just poured a ton of effort into our current “inadequate” jointer).

I would request a 12" width or greater personally, there are huge benefits to having a wider jointer. I can check again if my work is ready to part with that big 16" width Porter jointer I’ve been trying to get from them for years, haha.

I do not think it is a forgone conclusion that we have a huge expense upcoming to build out the dungeon. Many of us feel we should push off renting that space as long as we can till we are forced to take it, and even then we can take our time building it out. it need not be an “all at once” effort like the move was. Also, our bank balance is currently as high as it’s ever been at $51k, and our monthly income exceeds our monthly fixed expenses by about $2800/month. A good jointer would be a very reasonable big improvement to the wood shop.

Doug, Thank you for starting this discussion.

IMO Discussion of a jointer without discussion of a planner is incomplete. To me these are two of a pair. One without the other can’t truly square up lumber. We should examine the current and future needs of Hive members. We can’t be running a production shop, so the level of equipment should match our skilled hobbyist organization. To make a good decision, we need to develop a plan for both jointer and planner that ranges the good, better, best range of both capabilities and price.

Justifying the types of features desired, such as minimum cutter width, helical carbide cutters, bed length and quality reviews are going to be needed. and discussed before we jointly make a purchase proposal.

Dave Velzy

Hive13 Director

dvelzy@hive13.org

513-410-6174

“Unless someone like you cares a whole awful lot, nothing is going to get better. It’s not.” — Dr. Seuss

Agreed that jointers and planers go hand in hand, but wide planers tend to be a lot more available and less expensive than wide jointers, starting with the jointer and planning for a planer later makes a lot of sense.

Jointers the benefits are pretty clear as you get bigger/better, wider board capacity and longer bed means you can straighten longer and wider wood. We have had plenty of members make or want to make tabletops and similar, and bigger is better for jointers, even as hobbyists. I have always seen the hive as a place members can go to have access to more than hobbyist equipment without having to personally pay for professional equipment alone.

I fully support a new jointer. A jointer is used for two of the four faces on a piece of wood. The planer and table saw are only one surface (yes, there are work arounds). I agree that a solid 6-8” jointer with a longer bed is a required. I have the typical Ridgid 6” at home and it is very basic. A better unit at the Hive would be a welcome addition. A new jointer is a higher priority than a new planer, but that should be coming soon.

I agree that we don’t need production grade, but certainly mid-grade, comparable to our SawStop is justified.

Hi @Doug Schmidt, I’ll join your jointer discussion. If “our jointer” is the 6” Craftsman (HV0088), I have some skin in the game as that is my loaner to the Hive.

Know that I have no special attachment to it. I don’t have space or use for it in my out-of-town locations and am not around to support it at the Hive. If it is easy for the Hive to maintain and use it, that is GREAT, until it is not. If it is time for it to go, I’d favor finding it a good home and donating the proceeds to the Hive.

I do appreciate the value for the Hive to have a GREAT jointer. I have access to this https://www.greenvillewoodworkers.com/resources/Pictures/website%20photos/gwgshop/ShopPic015.jpg in Greenville. It gets well-supervised heavy use and excellent maintenance by the https://www.greenvillewoodworkers.com. I would love to see the Hive wood shop reach this level of capability, but it may take a while to get there.

As the Hive treasurer, I continue to share the news that the Hive is currently blessed to be cash-positive each month and that we need a strategic process for acquisitions, hence #proposed_acquisitions. As a Hive member, I would support the Hive having a GREAT jointer in the wood shop.

Thanks for pointing out it’s yours Jim, I hadn’t realized!

Okay, the very basics of milling rough furniture grade lumber to be ready to build something with. First things first, a bit of a safety lecture. It is very dangerous to run rough lumber, boards with no straight edge or flat face through the table saw. Without a straight edge or flat face there is not a solid reference against the fence or saw top. Without a solid reference the board can and will shift as the cut is made. As the board shifts that greatly increases the possibility of kickback. Kickback causes most table saw injuries. The primary function of a jointer is to flatten and smooth the first face of rough-cut lumber and then to mill 1 edge making it straight and square to the flat face. The primary purpose of a planer is to make the 2nd face smooth and parallel to the first face. You then run it through the table saw the jointed edged referencing the fence to make the final edge straight, parallel to the 1st edge, and square to the faces. I will generally make that cut 1/32 of an inch wide and use the jointer to remove the tool marks from the table saw. Your rough-cut lumber is now 4 sides surfaced and ready to be edge glued, cut to length or whatever the next operation is called for.

@Dave V while the jointer and planer are absolutely functionally paired, one is of limited use with out the other, there really is no reason that I can see that they need to bought/changed together like a bike chain and freewheel. The general rule of thumb is your planer should be double the width of the joiner but this is not absolutely necessary. Because I don’t know everything and wanted a bit of a reality check I ran up to Mueller this morning to talk to them about this issue and they concurred. We have a functioning planer. It is certainly not ideal but it performs its function. If we have the money to replace both in one fell swoop that would be ideal. If we don’t it would be much preferable to replace the non-functioning jointer and deal with a less than optimal planer for a while.

@Kevin While I was at Mueller I talked to them about benefits and drawbacks of 12+ inch planers. Their comment was we’d be happy to sell you one but there really is no reason why most shops need anything over 8”. They couldn’t even remember selling a jointer bigger than 8”. They feel that the larger jointers are much more intimidating for users, especially new users. The also said that the larger jointers are more dangerous. Since most of the lumber that we need to surface in in the 5 – 6 inch range you move the fence closer and that exposes the remainder of the spinning blade behind the fence. In my experience maybe 15% of rough lumber is 6 – 8 inches which makes an 8 inch jointer desirable. Mueller doesn’t keep larger jointer on the floor or stock them.

For those rare occasions that we need to surface wider boards we would have three methods to accomplish this at the Hive.

- Using a bandsaw, since cutting rough lumber on the table saw is dangerous, rip cut the board approximately in half. Being careful to use jointers marks and numbering very carefully mill the rough lumber and edge glue it back together. Done well and with some care the glue line virtually disappears. Cumbersome? Absolutely. But it works. This is probably the most common method and the method I’ve use for years.

- We have a large and rather nice CNC. Load the piece, thoroughly shim it so it’s nice and stable, fire the plastic brads through the piece and the shims, and surface. This method is probably best for large slabs, counter tops, tabletops and the like. Having never done this I can only imagine that it would work beautifully.

- Most jointers have rabbeting capabilities. Joint a little less than half the board hanging off the rabbet ledge, rotate the board 180 degrees and joint the other half. I’ve never tried this it sounds a little tricky, Oh, and you have to remove the blade guard which turns one of the safer pieces of equipment into one of the more dangerous. Not quite sure we could label it Deth Jointer 2022 in that configuration but…

While I was at Mueller I had them run a quote on 4 different jointers. The 2 Laguna 8” jointers are 15% off right now.

• Laguna JX|8 Quadratech – 8 inch 1.75 HP 110v power requirement – spiral cutterhead 20 cutter inserts. A very nice jointer which would be much more than adequate. $2,209.15 Laguna - JX|8 ECO QuadTec: I Jointer - Parallelogram - 1.75hp; 110v - Edward B. Mueller Co., Inc.

• Laguna JX|8 Sheartec II – 8 inch 3 HP 220v 1 phase – spiral cutterhead 54 cutter inserts. #2,719.15 This would be my 1st preference. Laguna - JX|8 PRO ShearTec: II Jointer - Parallelogram - 3hp; 220v - Edward B. Mueller Co., Inc.

• Powermatic 8” Parallelogram with helical cutterhead 54 cutter inserts 2 HP 230V 1 phase, $4,499.99. This would be my second preference. PJ-882HH, 8" Parallelogram Jointer with Helical Cutterhead - Edward B. Mueller Co., Inc.

• Laguna JX|12 12” Jointer $6,999.00 Laguna - JX|12 ShearTec: II Jointer - Parallelogram - 5hp; 220v, 1 phase - Edward B. Mueller Co., Inc.

And just for an idea of what new planers cost:

• Laguna 16” PX|16 Sheartec II $4,599.00 Laguna - PX|16 ShearTec: II Planer -5hp; 220v - Edward B. Mueller Co., Inc.

• Jet 15 “ Helical cutterhead $3,399.00 Jet 15" Helical Cutterhead Planer, JWP-15BHH - Edward B. Mueller Co., Inc.

• Powermatic 15” Heliical cutterhead $4,499.99 15HH, 15" Planer, with Helical Cutterhead - Edward B. Mueller Co., Inc.

As far as helical vs straight cutterheads I wouldn’t even consider straight cutterhead. The cost difference is minimal. The benefits of helical are huge.

As far as brands I’d be thrilled with Laguna, Jet, or Powermatic. I would be very uncomfortable with Grizzley or Shopfox.

I’ve had at least 4 projects I’ve tried to do at the hive that a 10"+ width jointer would have been hugely helpful for. Having access to the 16" one at work made two of those projects feasible where otherwise it wouldn’t have been. The “work arounds” all take a lot more time or are limited in how nice a finish you can get, which makes it unappealing, normally better to revise design to reduce stock width. I can’t think of any justification for that “planer double the width of jointer” rule… Every use case I’ve ever had, I needed them to be the same width

I also don’t buy that a bigger one is more dangerous, the guards are designed to cover all unused cutter head width. As long as the guards are in place, it’s all the same.

All that said, I’m not going to vote no on an 8" just because bigger would be nicer, haha. A straight blade jointer would be a no vote from me, but sounds like you agree on that.

I also don’t see any reason to get a planer right away. Adding one of them now would be bumping this into the $10k range, and I’m much more interested in having one of our next big purchases be a CNC plasma, as I see that is a better big improvement to the Hive as a whole

Kevin it sounds like we are really close on agreement on almost all points here. The only difference being is I lean towards the 8" but would still be absolutely thrilled with the 12". If we get more of consensus with the 12" fantastic. If we get more of a consensus with the 8" also fantastic. Win/win as far as I’m concerned.

As far as the safety issue moving the jointer fence and exposing less bed leaves the portion of the blade behind the fence exposed according to the folks at Mueller. I’ve never seen a 16 or 12 in actual operation. Just saw them at different luthier shops acting as very expensive shelving.

There is also the intimidation factor with a very large jointer and less experienced people. I’m sure that they would get over that though.

I don’t quite know where the double size planer rule came from. Just something I read sometime somewhere. Feels like a “Fine Woodworking” type of thing to me. I can’t even say I understand or agree with it, just throwing it out there for discussion.