After much deliberation over the last two weeks, both here on the mailing list and in the #woodworking channel on slack, I believe we are ready to vote to significantly improve the safety of our woodshop by replacing our old table saw (with it’s broken & missing safety devices) with a SawStop.

After discussing the various models and options, and a visit to Rockler and Woodcraft to see the saws in person, we have decided that the best value to us for the money would be the Professional Cabinet Saw (PCS) with the 3HP motor and 52" T-Glide Fence upgrade. While the Industrial Cabinet Saw (ICS) was noticeably a nicer, heavier built saw, it was not sufficiently nicer than the PCS to justify the additional $1000 cost. The PCS will be plenty robust for us, and will match or exceed the performance of our current saw just fine.

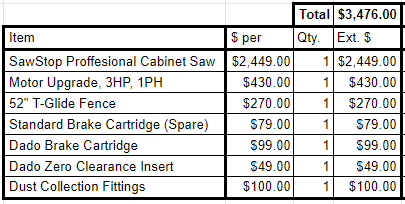

The list of options/upgrades I believe are necessary to duplicate our current saw’s capabilities, but with the much needed modern safety devices are as follows:

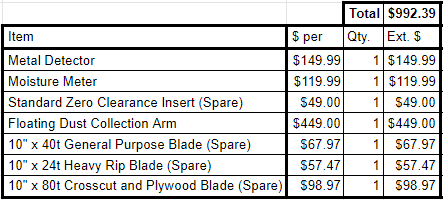

In addition to the above, I believe the following additional items, while not strictly necessary, will set us up for the best chances of success with our new saw:

The moisture meter and metal detector are for ensuring we minimize the chance of accidental trips of the saw’s brake cartridge (which costs $80 each time it goes off, plus the cost of a new blade) due to cutting green wood or cutting through nails, staples, or screws in reclaimed wood (like our stock of shelf wood). These tools are useful for all woodshop tools as well, and should help us extend the life of our jointer and planer blades as well as helping avoid unnecessary SawStop brake trips.

The spare Zero Clearance Insert is so that we can have one for making mitered/angled cuts without damaging the primary insert for making square cuts.

The Floating Dust Collection Arm serves as both an improved dust collection device that collects the dust from above the workpiece, but also acts as an additional safety device, preventing chips from flying at the operator’s face and eyes, and keeping fingers away from the saw blade.

The Spare Blades are important for two reasons, they ensure we have a backup blade in the event the saw brake gets triggered, and they allow us to keep the saw in service when we take our blades to be sharpened.

The only thing I believe we will need/want that is not included in this vote is an improved outfeed table that includes storage for the saw parts, accessories, and sleds. Austin and Amphay have volunteered to design and build one for us, but we decided that it will be easier to have that as it’s own vote once the design is ready (having the saw in the shop will make it easier to take measurements for the design too).

Both Rockler and Woodcraft have said that they can facilitate a tax-free purchase for us, and will give us 10% off the non-SawStop brand items (the blades, moisture meter, and metal detector). Shipping will be free so long as we pick it up from the store (I can borrow the flatbed or lift-gate truck from work if needed).

The total cost of the above items is $4,468.39. I propose a vote for $4,800, to give a $300 buffer in case we find there is something we forgot or didn’t expect we would need/want when we go to set up the saw. I do not expect to need this buffer.

This vote will end one week from today, during the meeting on Tuesday, September 7th, 2021.

Thank you everyone who contributed to the discussions surrounding this. There were MANY options, with MANY subtle pros and cons that everyone really pitched in to help understand and evaluate.

Thanks,

Kevin M.

Hot Crafts Warden (and former Woodworking Warden)