Daniel, are you open to having a group help with this project? Maybe delay the vote for a budget till a few people (yourself included) can get together and hack at the machine with the current parts to really drill down to what needs to be purchased given the number of items it sounds like people are willing to donate from their own stock piles?

A new machine of that size would be close to $3K and up unless you built it from scratch like a Voron2 or Hypercube Evolution. Right now there aren’t too many machines you can buy that are that big without spending thousands of $$. If the frame of the Gigabot is in good shape then your real cost to upgrade it would be in the control board, high quality GT2 belts (Gates), the Linear motion system and any hotend and bed components.

The real issue with the Gigabot is the fact that it uses antiquated rubber wheels in V-channel with Eccentric Spacers to keep everything aligned, that is a recipe for inaccuracy on a platform this large. Most if not all printers these days either use linear rod or linear rail so if there are problems keeping the bed level then that should be looked at as well.

I kind of agree with Will in that it would take a good bit of $$ to upgrade it to a consistently accurate machine. I’d love to help with it no matter what is decided but it may take a few smart people to sit in front of the machine and take a hard look at what it really needs.

I have half a dozen or so Android tablets laying around. I am more than willing to donate one of them to be best buddies with the wifi controller for the gigabot so that there is an option for people who don’t have smart phones. (gasp)

I know nothing of the 3d printing jargon so I’ll keep my nose out and offer to be helpful where I can.

-DaveB

Wow, this conversation thread exploded more than I thought it would, I am gonna try to respond to everything mentioned here, if i miss something, let me know:

I did miss Dave 3.0’s comment. I dont think the Gigabot is ever going to be as user friendly as one at the library. The settings for them have been tweeked and tinkered with by the workers at the library to make it as plug and play as possible. Machines like the gigabot are not made for that, kinda like the CNC router. Things like the PEI sheet, BL touch and the Duet2 makes its alot easier to use than its current hardware would allow.

Daniel, that is fair and I totally agree with you on all points. Obviously everyone is interested in having a usable, reliable device and the nature of the 3D printers is it requires a bit of finesse to coax them into making good prints. And everyone needs to have reasonable expectations. My statement earlier comes from my experience of getting results that are simply laughable and my expectation has been reduced to “for all intents and purposes the hive does not have a 3D printer that is worth bothering with”. Since Kevin has urged me to try again I will.

While not trying to derail this thread, the Ultimaker is working much better now after Jeff’s efforts. We did just have the bourdon tube be not quite pushed into the head which caused the filament to jam up against an edge. I marked the bourdon tube so the correct length is visible and becomes less touch-N-feel to get it right.

If people work together on this more complicated equipment and setup a nice stable base, then others are less likely to try their “fixes” to get it working properly. Most people don’t mean harm, they just want to get stuff done.

The warden concept is for a person to “own” an area for supplies/cleaning/maintenance but I don’t have any issues with someone managing a particular piece of equipment (like Jeff is doing with the Ultimaker). Basically a note that says “This machine is working great with these settings (have setting easily documented), before jacking stuff around please contact XYZ on Slack, or the mailing list, to troubleshoot any issues.” A nice FAQ can go far to stop people from tweaking things into oblivion.

I’ll donate a couple of old android tablets (nooks, kindle fires, etc.) that have been reset next time I am down at the space. They literally have been in a desk drawer for at least a year so they would have a much better home at the hive. They all work fine - they’ve just been replaced with faster models with longer battery life.

-DaveB

Brad, I agree. But do you mean bowden tube? I had to google bourdon tube, https://www.flowcontrolnetwork.com/what-is-a-bourdon-tube/ I dont think thats used in a 3d printer.

Dave, thats awesome!

Ha. I was typing too fast. Since I am a mechanical engineer bourdon tube comes up in my mental database before bowden.

Since it is a “real” thing it doesn’t show up on spellcheck.

Although a bourdon tube 3D printer would be pretty cool . . . . . Maybe use the flexing of the tube to shift the nozzle. . . . . Sounds like an infinitely useless project (as I add it to my list).

I realized i didnt put a time for this vote. It will be next week 7/16.

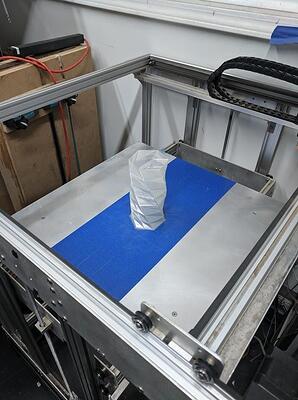

I spent a fair amount of time yesterday straightening up the FabLab and moved the Gigabot over to the wall by the 3D printing area. That should be a more appropriate permanent home for it so it can be leveled and not need to be re-leveled every time it’s used because it’s been moved to a new spot were the floor is a completely different shape.

If this rebuild gets going and it looks like the printer is going to be usefully reliable, I’ll gladly build an enclosure for it so it doesn’t get stuff set on it’s build plate all the time (and gains the other benefits of an enclosure).

Thanks,

Kevin

Kevin, that would be awesome, overall it has its own enclosure based off its build, and with all the acrylic we have we can put walls on pretty easily, unless you had a different idea in mind I would love to hear it.

Nah, I was just going to cut an bolt in place acrylic panels.

Same idea I had! Great minds and all.

I saw with the fablab cameras where the Gigabot was moved to, I see the back is facing the cabinet how much room is accessible from the front? There is a table blocking line of sight on that

We just moved it over there, didn’t worry about orientation since it currently doesn’t work. It’s orientation and exact spacing to it’s neighbors probably needs to be adjusted still, but the thing is easy to move, it’s not heavy at all.

I’m unsure if I’ll make our next meeting, so I’ll register a “no” vote here.

While the suggested Duet control board is superior to the existing RAMPS board, the Gigabot currently works. We have configuration and documentation problems, not hardware problems.

Reflashing the Arduino with an updated Marlin, and possibly adding a Raspberry Pi with octoprint as a control interface, seems like a more direct path than completely replacing the already functional and tuned electronics. We might need a few odds and ends to smooth out the printing workflow, but I think the Hive or our members (particularly Jeff B and I) have them lying around.

I went by the Hive on Friday, strapped an old Pi to the Gigabot, and printed a part to ensure I wasn’t holding unrealistic ideas about the machine. The first attempt was entirely successful.

$500 to $700 is just an exorbitant amount to spend for improvements that will not result in better prints. We already have well over $2000 sunk into the Gigabot. It’s time to stop throwing money in the hole.

- Ry

The Duet 2 wifi Control Board is only $200 of the vote, we have an antiquated cobbled together setup for our control board which isnt the best fit for the printer, much less of a fit for ease of use for hive members. The heated bed isnt hooked up to it, because it was determined years ago that the board and/or marlin couldnt handle the setup, and it started collecting dust shoftly afterwards, This is something the Duet 2 can handle. I believe its time to move past the arduino with attachments to more modern technology.

I am going to disagree with you on that last statement Ryan, “$500 to $700 is just an exorbitant amount to spend for improvements that will not result in better prints.” I am sorry you feel that way, but that is just not true. The Duet board alone has better stepper drivers, which that factor alone can get a better print, the board has other improvements over our current setup which also can improve print quality. (Also TL smoothers will help with that, they would be allocated within that extra $165 if the funds were available, if not they are around $20, I am sure we can find the funds for that.)

The upgrades I put up for a vote will result in more successful prints, even from someone who doesnt have the experience on printers as Ryan or I, it will be less wonky of a setup, and more ease of use. The $2000, that appears to be what we bought the printer for. I am sure more funds were spent to buy it from guy who loaned it to us, but I cant find any of the votes for the glass plate, the bed heater, the lost bed adhesion sheet on the mailing list, my google-fu failed me. Also this is one tool that we have that nowhere open to the public in or around Cincinnati has to match. The public library’s printers dont have anywhere near the print volume, the Manufactory only shows a Makerbot Replicator 2 (which is smaller than a CR10.) On top of that, the gigabot currently is far from a easily usable printer. To start the aluminum board is heavily warped for a 3d printer, I know we purchased a glass plate for it to help with that, but the sensor we have doesn’t work with it, part of this vote fixes that. Even if we decided to trash this gigabot altogether and replace it, for the giagbot 3, the kit alone is over $8000. The cheapest replacement i could find for the same build volume is $3500 for a brand I never heard of. When looking at it that way, $700 isnt that bad of a price to get it up and running.

After watching Ryan print this last night I am pretty convinced that while the Gigabot needs some TLC, we do not need a new controller.

While not perfect, that print is pretty nice looking, and that was with absolutely no tweaking or calibration other than playing with the extrusion multiplier for the first layer. There isn’t enough gain to be had in print quality from a slightly better controller and slightly better stepper drivers to be worth replacing working equipment, particularly since this machine will always be relatively slow due to the mass it has.

I think with he amount of stuff that has been offered up as donation toward getting the machine running fully, a much smaller budget would be appropriate (if we end up needing anything at all that can’t be found in the hive or member’s stashes already).

The things that make sense to me are:

- Flash the controller with an appropriately configured and up-to-date version of Marlin (free + effort)

- Set up a Raspberry Pi running OctoPrint (probably can find a member to offer one up for free + effort)

- Add a BLtouch probe to be able to auto bed level on the glass we have ($35)

- Add whatever signal amplifier/conditioner is required to get the current controller reading the bed temp (If we don’t already have something, guessing $50 + effort)

- Add a relay or whatever transistor device is required to allow the controller to turn the heated bed on and off (Probably already have something, otherwise guessing $15 + effort)

- Add removable enclosure panels for cleanliness, protection, and heat sensitive prints (free using acrylic at the hive + effort)

Based on that, I see no reason we would need to spend much more than $100 right now to get the machine running. While we could probably cover those costs in the warden budget over a month or two, I’d support a vote for $200 to allow a little wiggle room. Once there have been a few weeks of strong elbow grease trying to get everything dialed in, if it turns out we need a something more, we could have another vote for whatever comes up.

I’ll be there Tuesday to discuss more. If we revised the vote down to a lower amount, would that reset the vote timeline?

Thanks,

Kevin M.