Hello everyone,

Matthew,

Can we mill a t-slot table on the RongFu?

I have to check but I think so. We only could use it for metal or plastic machining.

Do we have drill rod or t-slot mills?

Not that I am aware. it will be an item of my proposed BOM.

I want to buy ( if necessary) a t-slot cutter that is dedicated for the 1/2" nuts (https://www.grizzly.com/products/T-Slot-Cutter-1-2-/H5912). Before using it, it is necessary to mill a slot with an other bit to allow the T-slot cutter to pass.

Do we have access to like >5/8 aluminum plate?

We (Ryan, me and Jim) have first decided to give a try with a plywood board. Then, we would maybe switch to an ABS board. In my opinion, it is useless to put an aluminum board on the Shapeoko. the frame of this small CNC isn’t strong enough to mill big metal part AND after the slot milling we still need to level the board with the spindle. For now, leveling a aluminum plate with the actual “dremel-like” spindle will result in a crappy surface…

As we say in French, using aluminum for that it like give marmalade to the pigs. it’s not worth it.

Ryan,

’ll take item #2 on your list, and finish printing the cable chain this week.

Thanks! i don’t know how to 3Dprint for now. I really need to take some classes at the hive before buying mine.

For #4, yes. Please do assemble a sample bill of materials for the motor controller you have in mind. We can review it and get a vote on the docket for next week. It seems that Hive members most commonly order parts from Mouser or Digikey. I’ve had good luck with http://www.circuitspecialists.com/ for various components as well, and they stock a wide selection of reasonably priced power supplies. Any of these would be a great place to start if you know precisely which components you’ll require.

OK, it’s already on my bucket list. I have check on circuitspecialists. They have a power supply that could fit with our needs.

As far as the work holding system is concerned, I’d like to review the hive’s existing collection of router bits both to see if we have anything on hand, and to confirm our available collet sizes.

OK, the only available collet on both the “dremel-like” and the DC spindle are 1/8". The collet size ise ER11-A. There is some available for 1/8, 3/8, 1/4 shank diameter at Inventables for around $5 each.

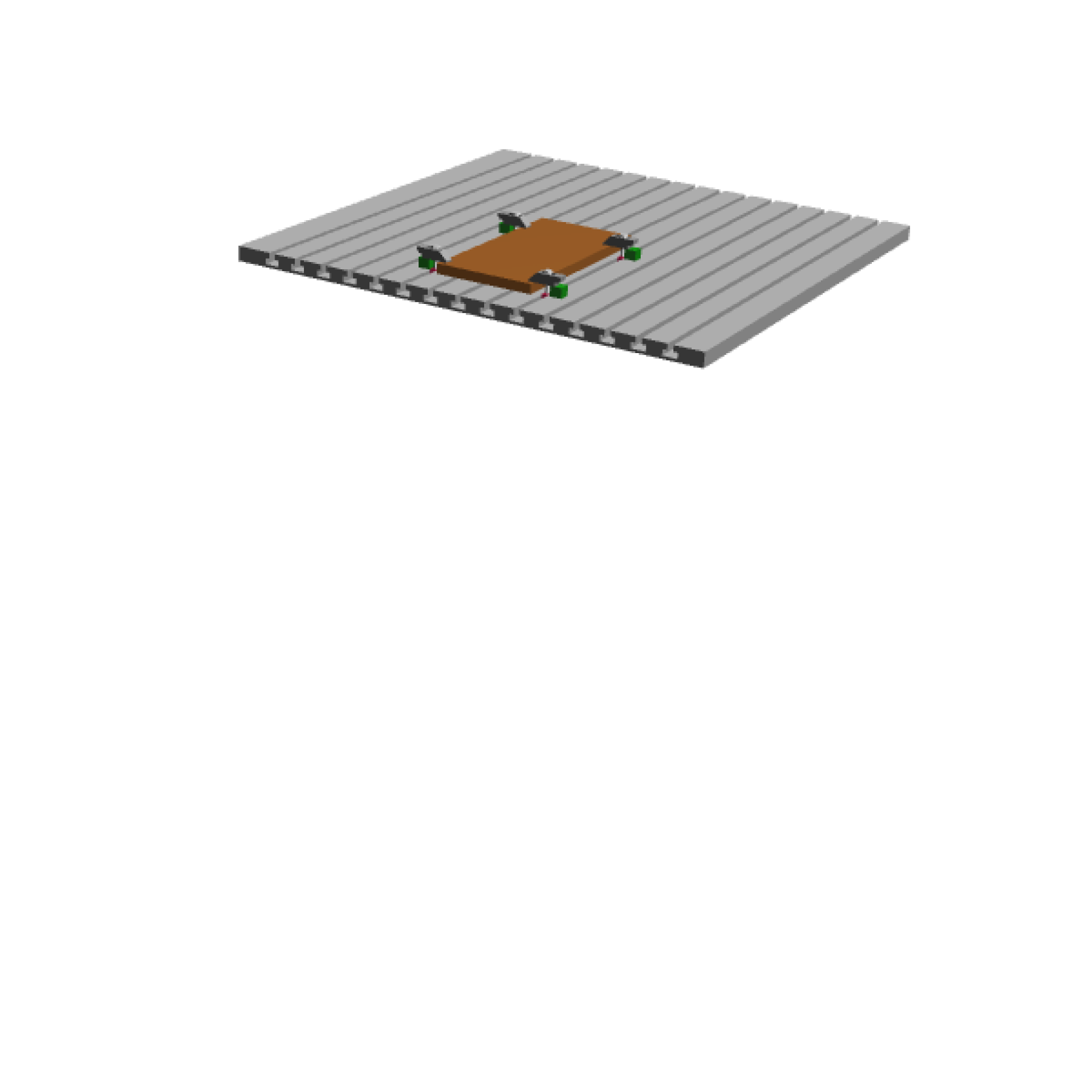

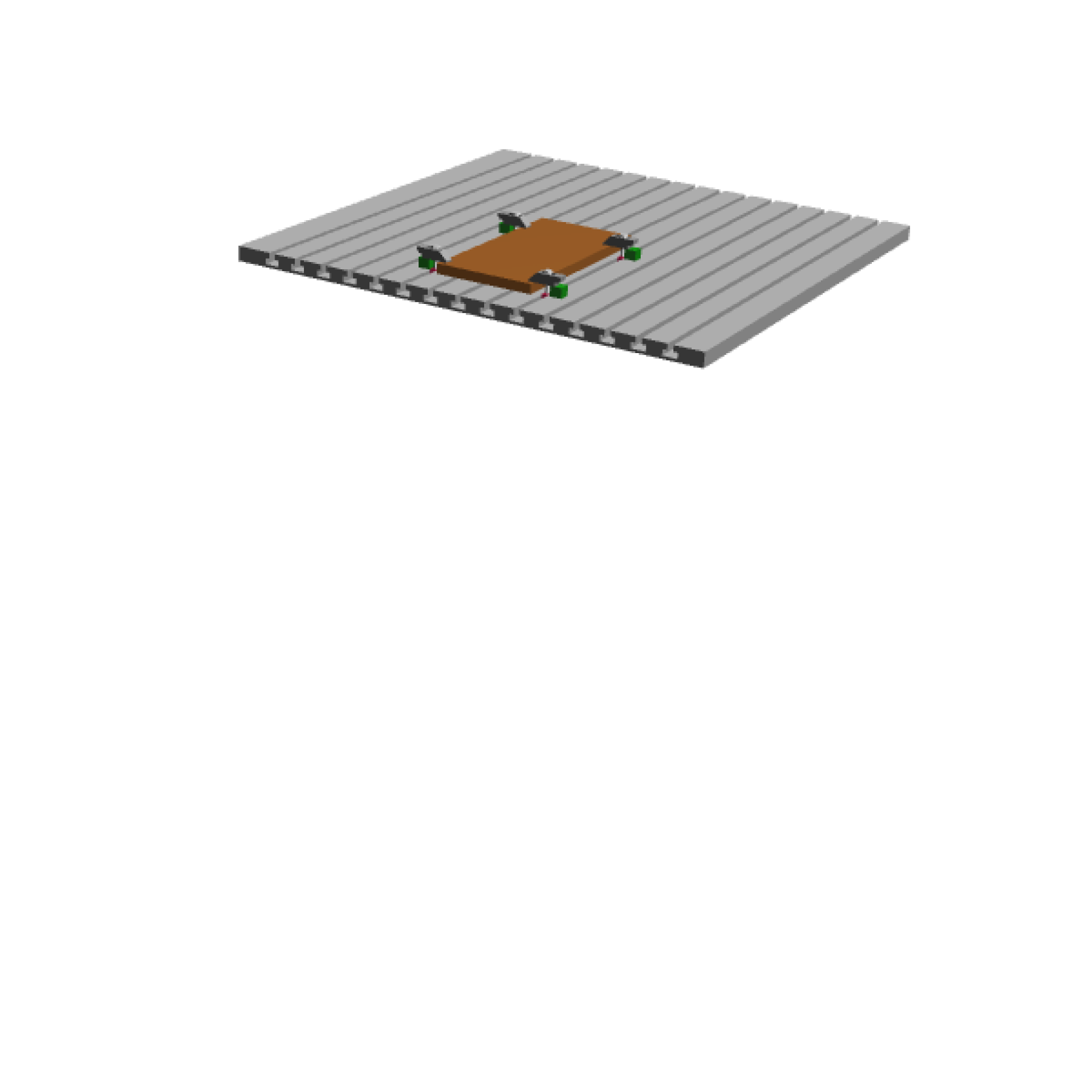

I have check on my pdf3D files and it’s working fine. I have add a picture in attached files. Maybe you have to update your acrobat reader version.

Julien

locking_system_Shapoko.pdf (101 KB)

This will probably cost some money…

This will probably cost some money…