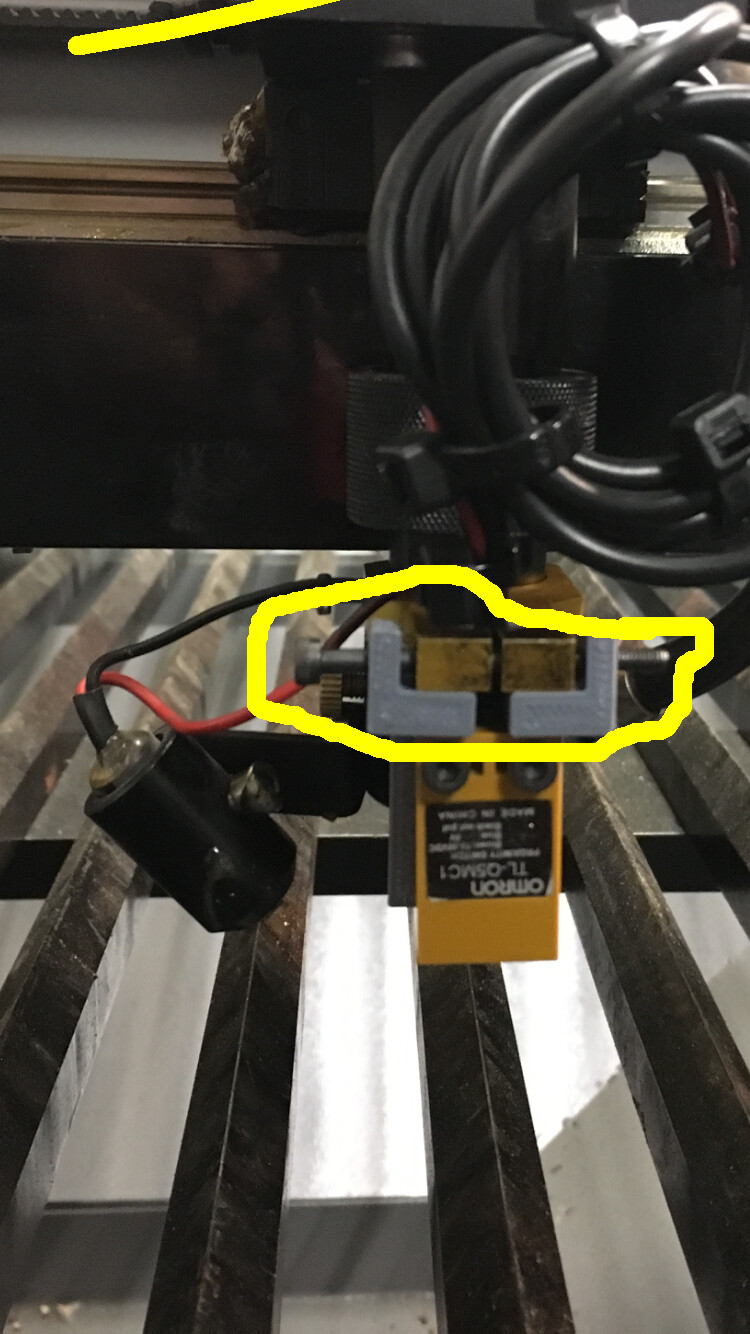

I have mounted the laser sensor to the big laser and it’s untested.

Before the mob comes and beats me for not doing this to their satisfaction remember these things

-

I never saw how this was in a working manner and have no reference to go by outside of the wiki

-

I worked only with what was easily or quickly available to me at the time

-

The Large laser has sat dormant in a “non fully functional” format as long as I’ve been a member…4 months(maybe before this)

-

The Hive is as much a Do-Ocracy as it is a Re-Do-Ocracy but let’s not make this “Undo-Ocracy”

Some things that are definitely “less optimal”(as brad would say).

- The large cable with several zip ties(I’d like to make this shorter with a little slack), Before starting I had no idea how long of a cable I would need so I chose not to cut it at all, so it is untrimmed.

- The large D3 inside the yellow circle is unappealing to me but was what I could find to work with(any ideas the piece uses the same threads as D3)

- The thickness on the plane with two holes for mounting the sensor is too close to the sensor I was unable to mount the sensor with bolts and is instead relying on the threading through the plastic, which I was unaware of this definitely being required prior to starting so I had drilled the holes slightly larger and made through holes(so either editing the model or a reprint but not drilling through holes on this plane will solve the problem, unless we would like to use glue I am open to suggestions).

Some questions?

- Is this mounted to the correct area?

- Seemed like the most logical area1. Is this the correct height?

- Again seemed logical1. Is this particular rotation correct?

Thanks to Ryan, John, Brad and Lorin each having a hand in getting this together.

As you said there is some room for improvement, perhaps editing the 3D printed piece with some slots for nuts

As you said there is some room for improvement, perhaps editing the 3D printed piece with some slots for nuts