Perhaps you should contact the neon works guys at the Sign Museum to see what they use. They bend a lot of glass.

I have talked to them, and I am familiar with their equipment, not sure how applicable what they use is to what would be best for me to get for this… they run production, much easier for them to justify convenience/lifetime cost over initial purchase cost vs. me buying all this for hobby use.

I have ordered all the tools needed to get this torch up and running, along with a large assortment of both clear and color glass rods. All I need to get now is gas, which i think I will have delivered to Hive13 unless someone can help me pick it up from Praxair down the street from Hive13 (I don’t have a truck). If anyone has a 20 lb. propane tank (like for a grill) or 125 cu. ft. oxygen cylinder they don’t mind donating (even if currently empty), it would save me a lot of money vs. buying new cylinders. the gas refills are only ~$40 vs. and extra $250 for new cylinders.

I am going to set everything up on one of the folding tables in the main area. all members will be free to use the equipment, but since it’s all been paid for out of my pocket (it’s about $1600 worth of equipment, gas, and glass), I am going to put a “donation” bin out and a suggested dollar amount per clear and color glass rod used. I’m not looking to recoup the equipment cost, but it’d be nice to be able to cover refilling gasses and glass stock.

I’ll also type up, print out, and laminate some basic equipment operation, safe torch use, and annealing instructions to be posted with the equipment. Once I have had a chance to play with everything a few weeks I can also do some demos/classes for anyone interested.

Thanks,

Kevin

Super cool, thanks for setting it up.

I’d highly suggest putting your name on everything you brought to the Hive. Saves a lot of discussion if you take it back.

The consumables (gas) should come out if the operating budget. The rods can be thought of like Ryan’s square tubing purchase (payback as used)

If it becomes a hit, you could present the Hive buying the gear if you like.

Good times,

Brad

No problem, It’s something I’ve been itching to do forever.

Yeah, I’ll be etching my name on every tool when they come in. Are you saying the cylinders could come out of operational budget, or just refills?

I’d love it if people got excited about the glasswork and it got used a lot. it’s a VERY fun hobby. It’d be super cool if we could eventually upgrade to a bigger torch that can do borosilicate, tubing, and vessel work.

oh, one thing I had not addressed:

for eye protection, torch work does require better eye protection than our standard clear plastic safety glasses.

I am buying myself a pair of nice Phillips 202 glasses, but they will be just for me, as they are VERY expensive.

might it be a good idea for Hive13 to buy a few pairs of the poly-carbonate versions?

https://www.mountainglass.com/Disposable-Viewing-Filter-Refracted-Fire

might be good to have a few dozen of those around for demos/teaching too. they are not good enough for the person sitting at the torch, but good for people standing nearby.

If the tanks are for use at the Hive I would say the Hive would pay. We can talk in the next meeting. Is it a deposit or purchase?

It's purchase. They do offer rentals, but the cost is high enough it just makes sense to purchase the bottles. Rental would make sense if you just needed it for like a week or something.

I created a slack channel for glasswork discussion if anyone wants to join:

Join our Slack workspace with your @hive13.org email: Slack

Channel is #glasswork

Only thing left to get is Gas, then I’ll start working on getting everything set up, tuned in, and instructions written up. I will ask that no one use this equipment till I have had a chance to fine tune startup/shutdown and annealing procedures, but once I have that stuff dialed in and written down this should be open for anyone to use.

I got gas, am returning the truck I borrowed, but I'll be back later if anyone is interested in helping get stuff set up or excited to try it out

The torch is up and glass can be worked! I'm still working on making sure the annealer is set up properly, most of what iade yesterday cracked, though I suspect that wasn't the anneal cycle, but that I put the pieces in the annealer too cold.

I'm also blowing through gas... I'm going to need to trade in these cylinders for larger ones.

The oxygen regulator I had also blew a gasket, so I am currently using the one that was in the oxyacetylene torch kit in the welding room. I have a new pair, gas and propane, on order.

Dude, can I make a sweet bong with this?

No, you can make a sweet water pipe for smoking tobacco.

Duh.

-Dave B.

Okay, that sounds cool too. The tobaco water pipes that are made from potatoes and hot glue get moldy – glass would be better.

This torch is pretty small for doing blown work or borosilicate work. It can do some, but limited to small sculpture work, or up to around 19mm thick wall tubing. I don't have any experience with it myself, but my understanding is that most glass pipes are a good bit larger than this torch can handle.

I would caution anyone who sees this and thinks they might sneak in an attempt anyway that pipes MUST be made out of borosilicate glass, and it MUST be annealed properly. If either one of those warnings is not headed, it WILL crack/explode when you try smoking from it because of the heat. None of the glass in Hive13 right now is borosilicate, it's all soda-lime soft glass, and the annealer is programmed to anneal soda lime glass, which anneals at roughly 200 degrees lower temperature than borosilicate.

If you try to make a pipe at the Hive, it WILL explode in your face when you try to use it.

Just say NO.

Sorry that reads funny. I was referencing the old “say no to drugs” campaign.

I have been working on getting ready for certification classes for the glass tools. The biggest thing I wanted to get done was write some basic safety and operating instructions for people to reference after being trained for certification. Would anyone be willing to read and review the instructions for me? I’d also like for someone with gas/oxygen torch experience sit down with me to validate the instructions at some point before I do the first certification classes. If you are willing and able to help with these things, please message me either on slack or by email, thanks!

I am also ready to start scheduling some certification classes. If you would like to learn to use the tools and get certified, please email me or message me on slack to let me know you are interested and let me know when you might be available. The certification classes will likely take a few hours, an hour for basic equipment and safety orientation, then 2-3 hours to learn the basics of actually working the glass. Because of this, weekends are likely to be best, though if you need a weekday let me know and we can make it work (possibly my Thursday warden hours or I can make it in early before the Tuesday meeting to do a bit before and bit after the meeting).

My email is kmcleod@hive13.org or you can message me at Hive13.slack.com

Thanks,

Kevin

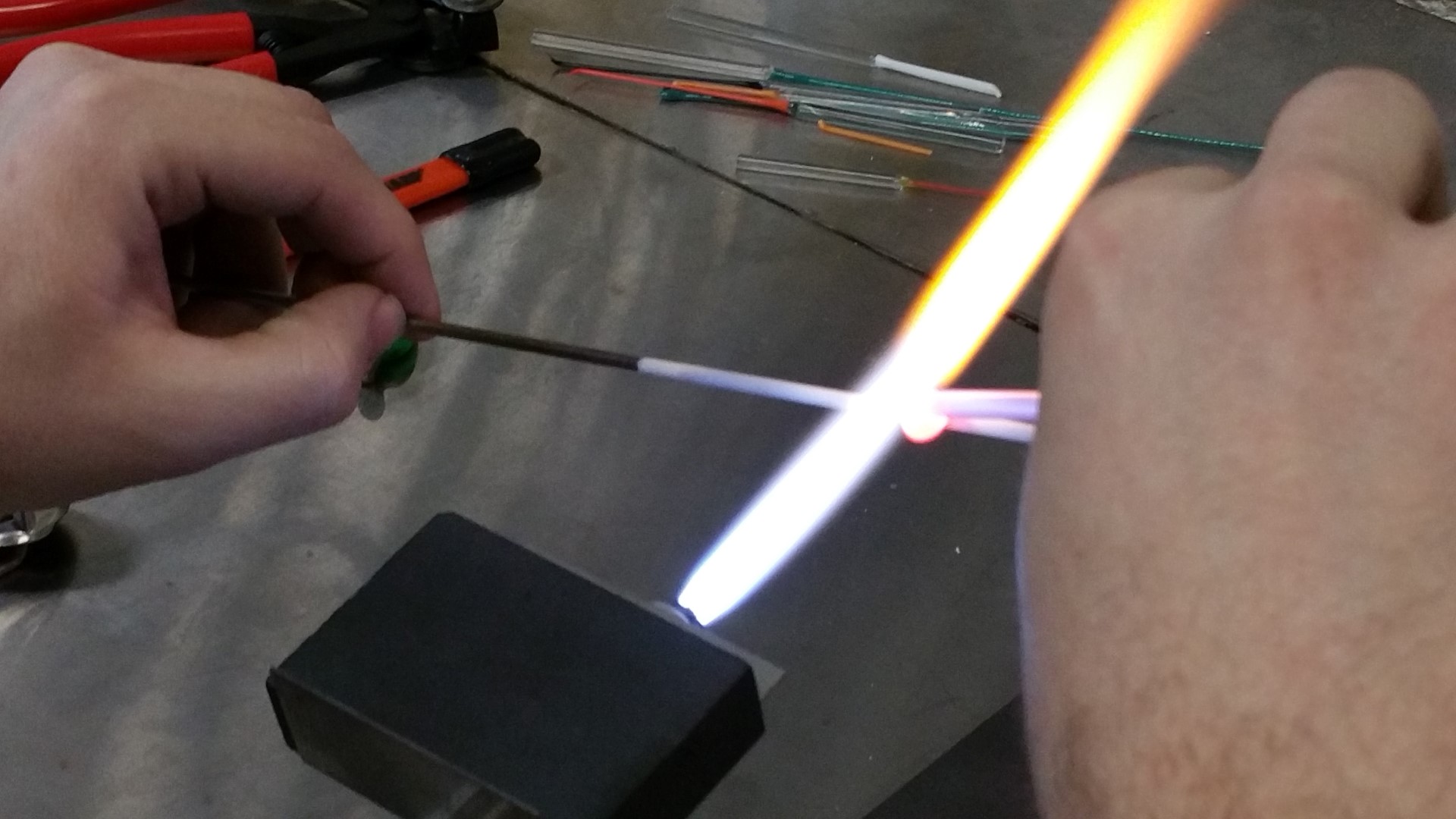

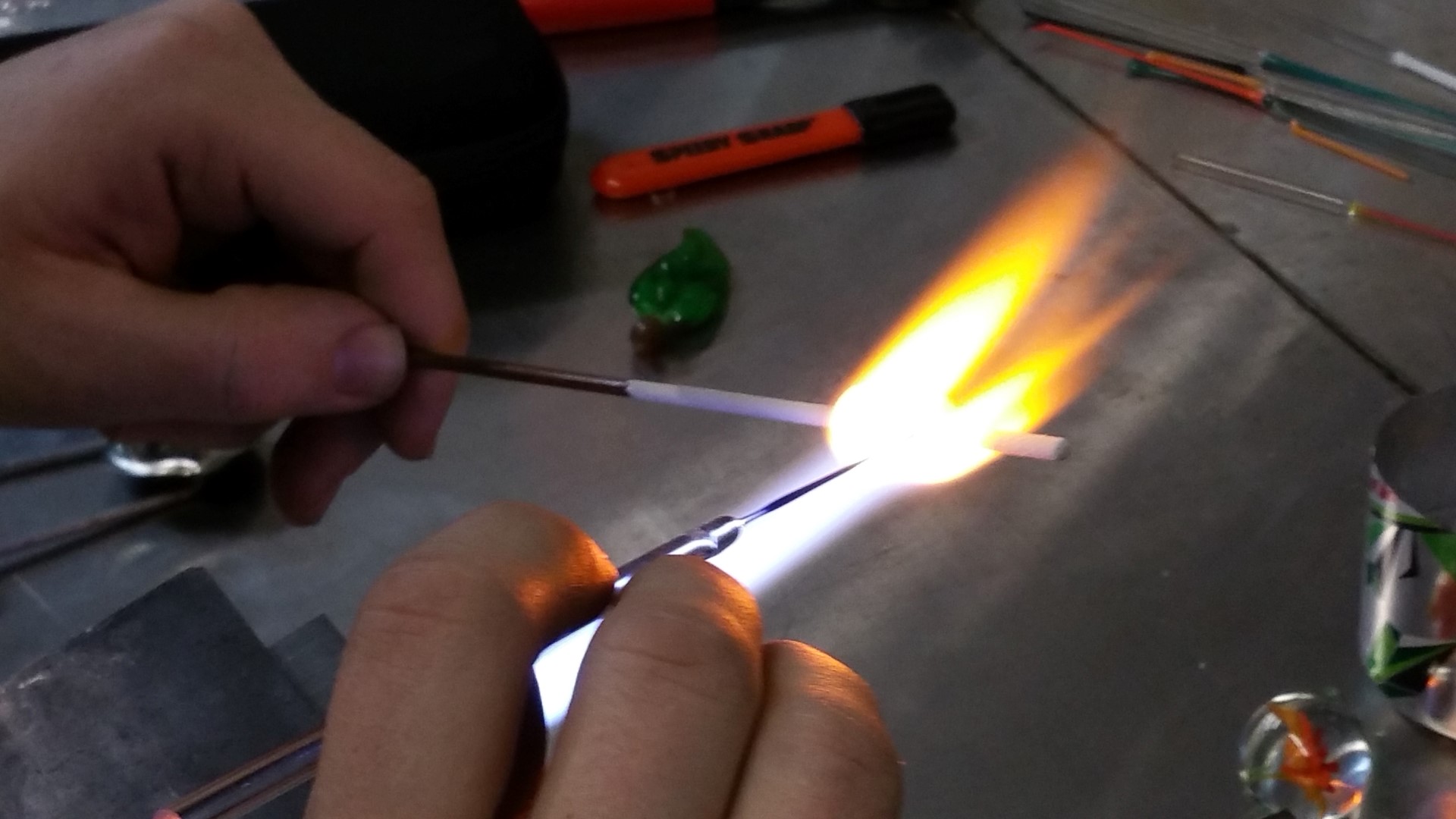

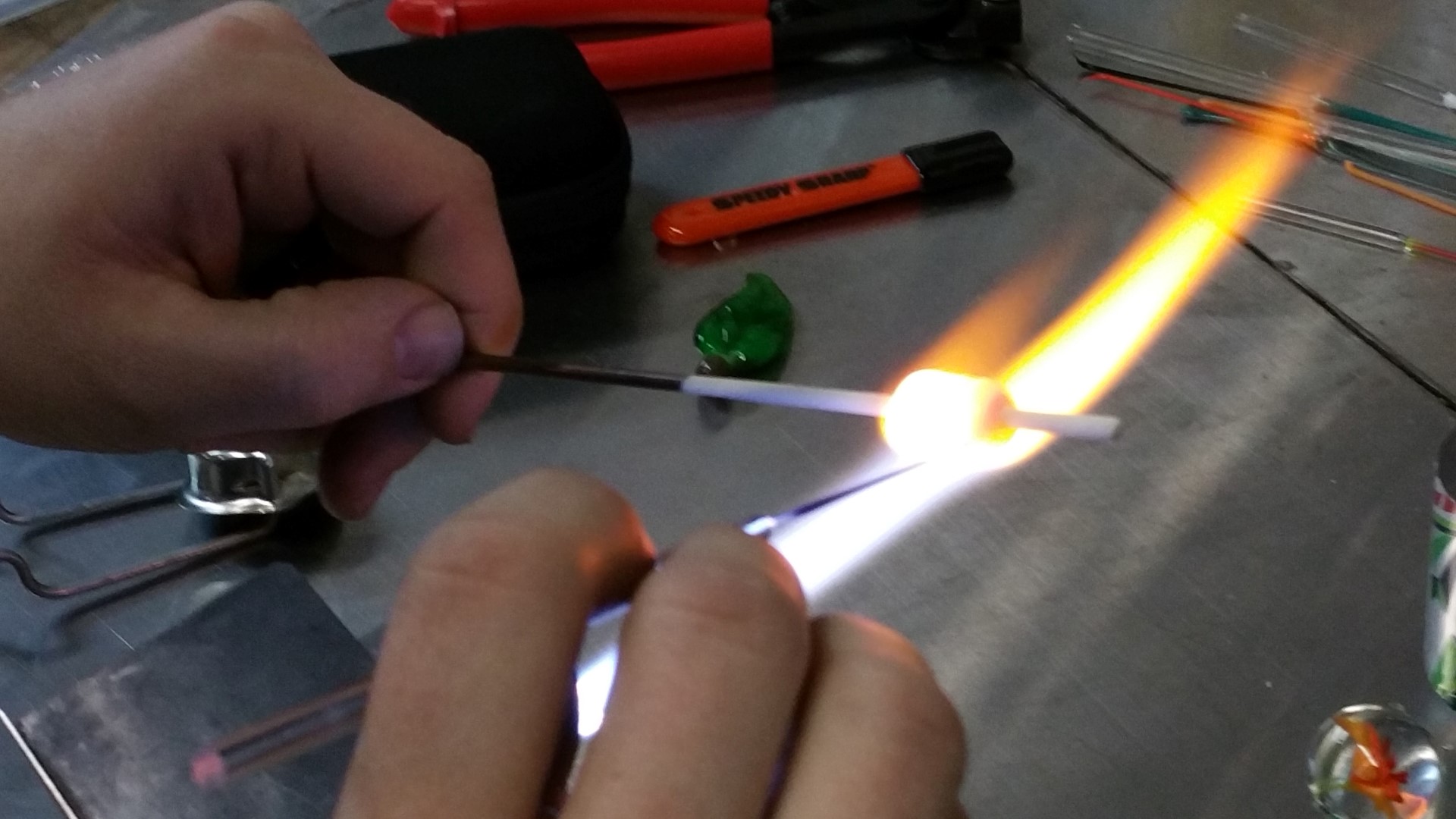

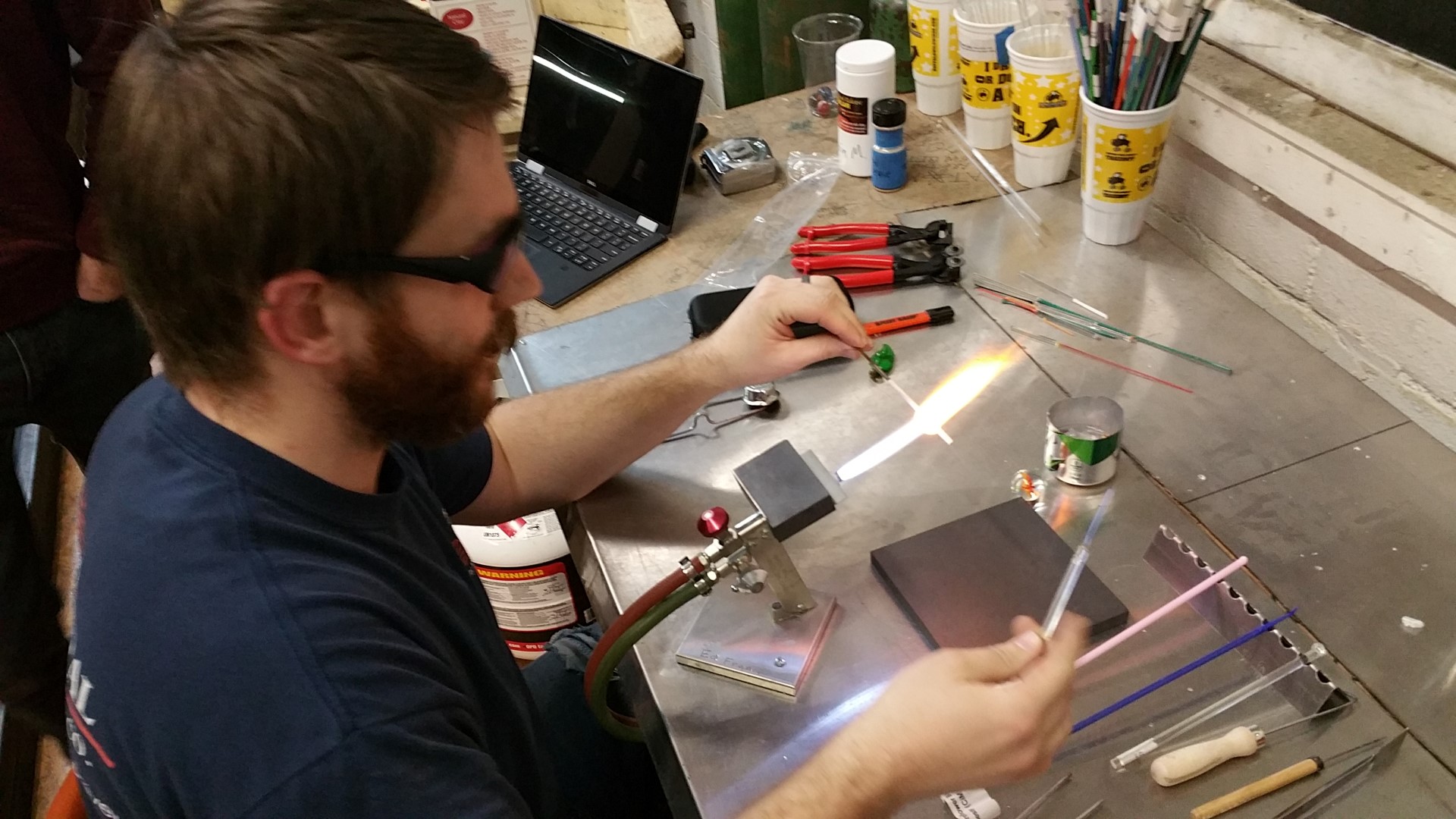

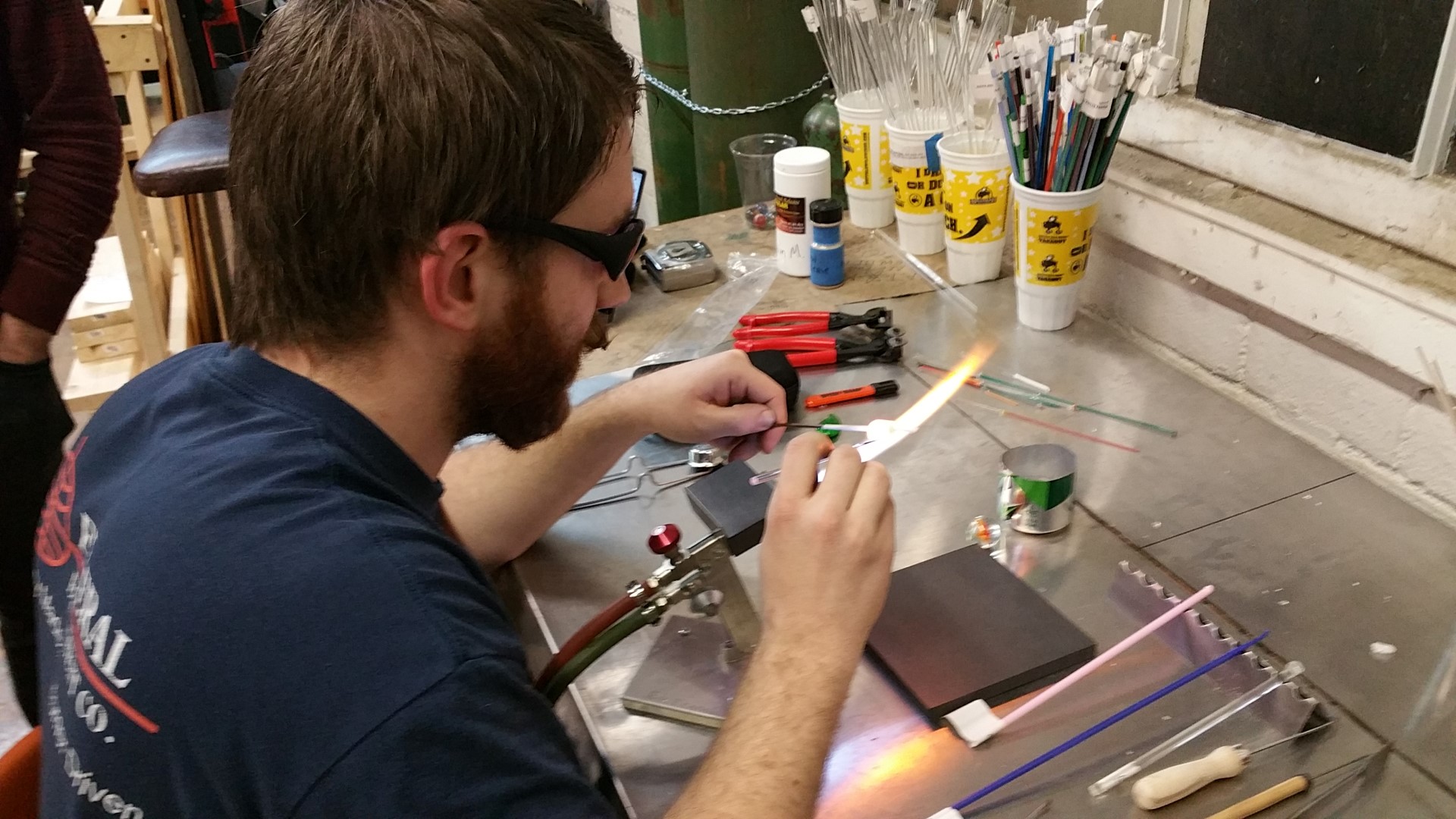

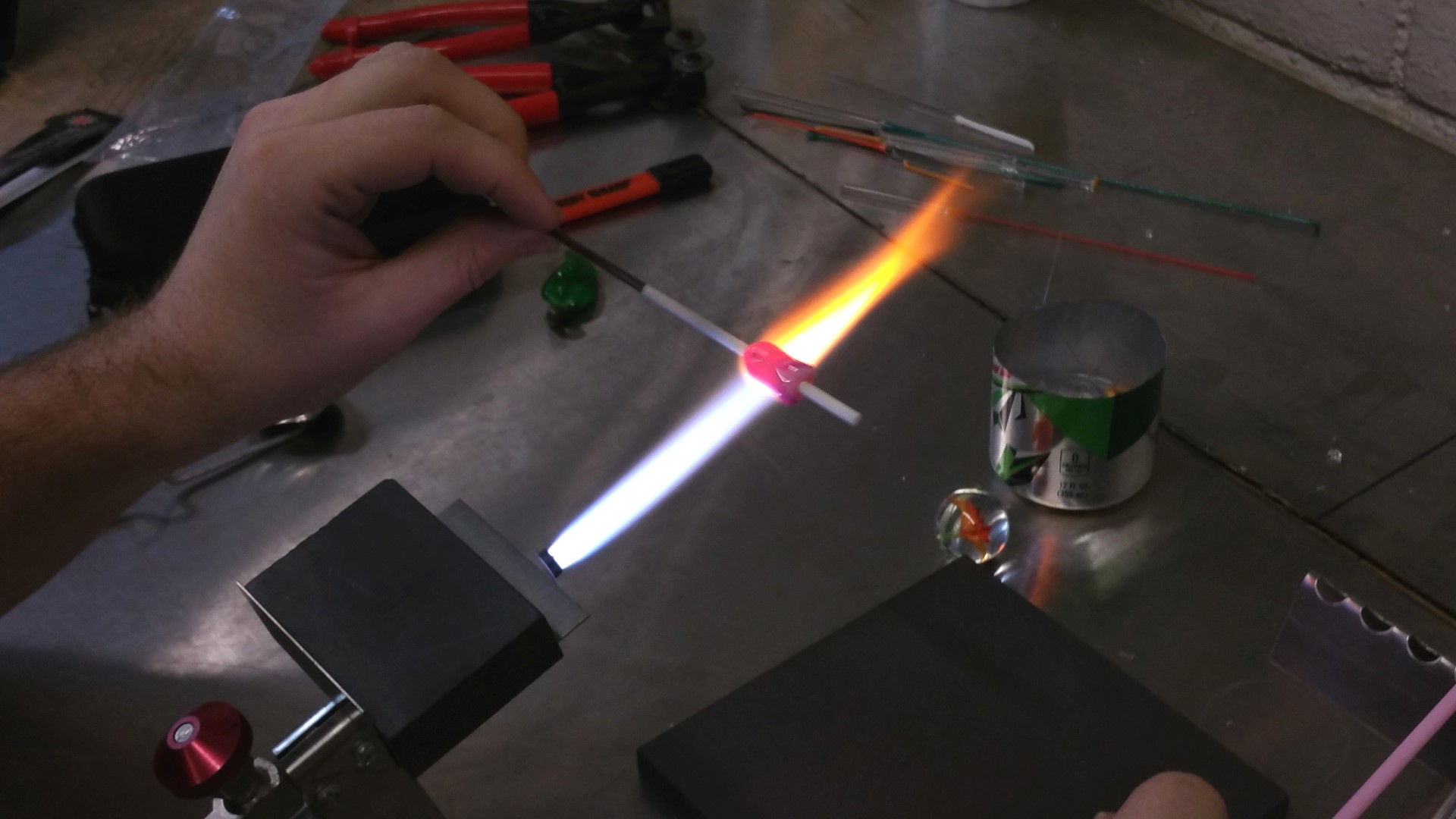

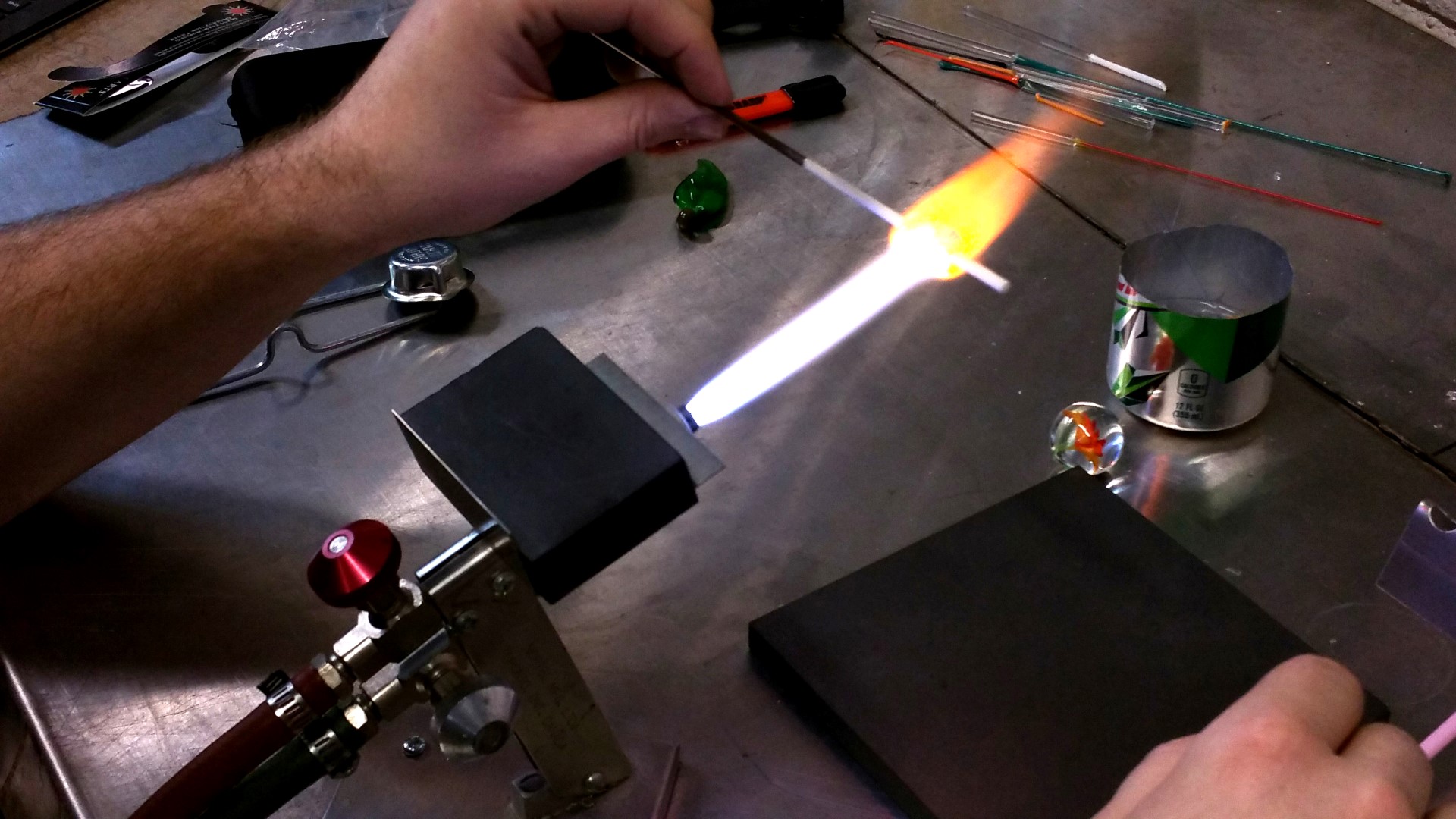

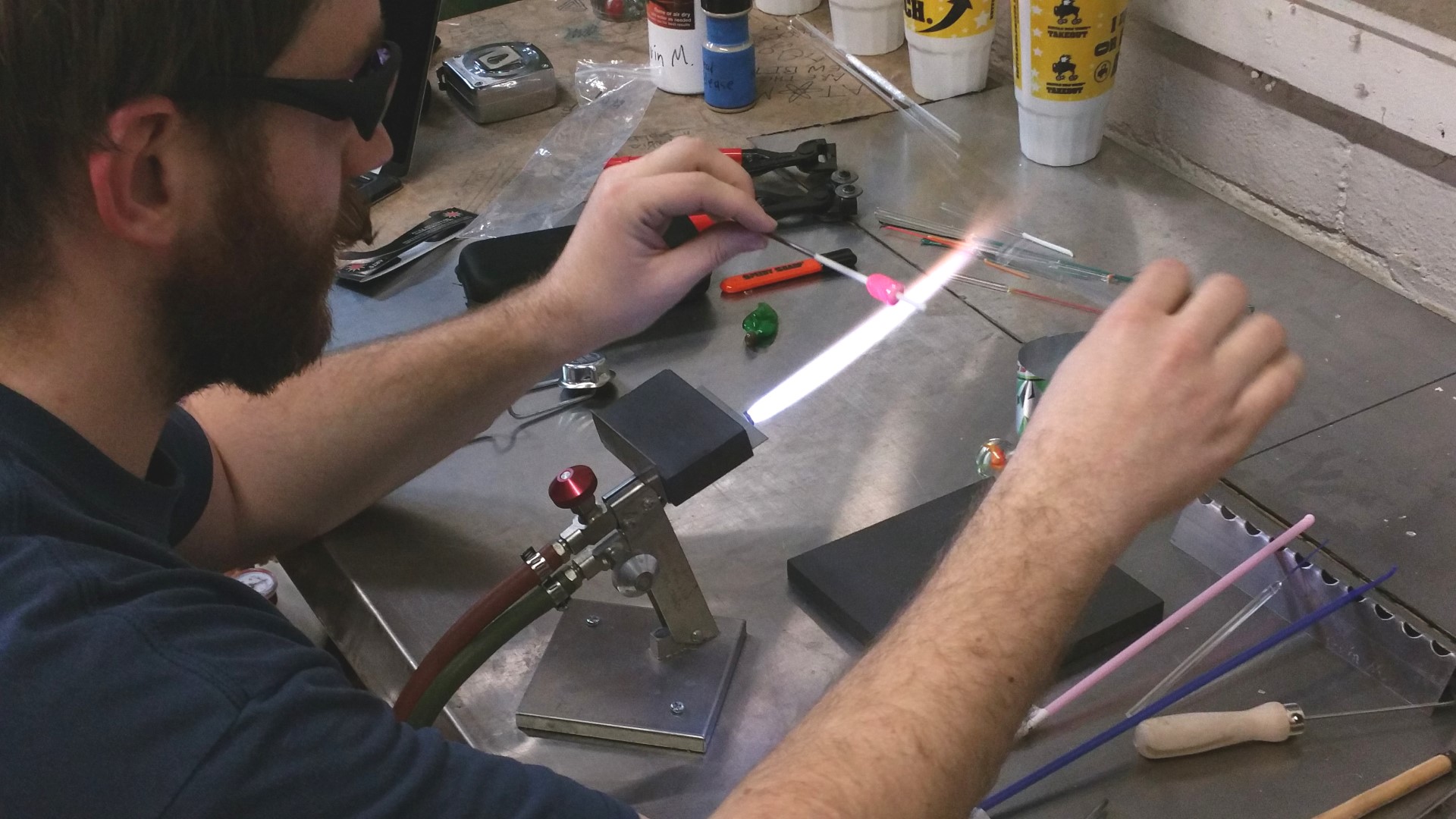

Some pictures,

they can be useful to promote certification classes …

regards,

Vicente