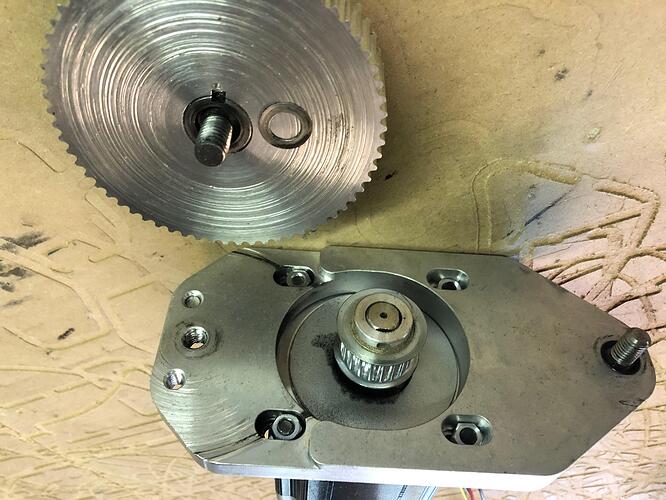

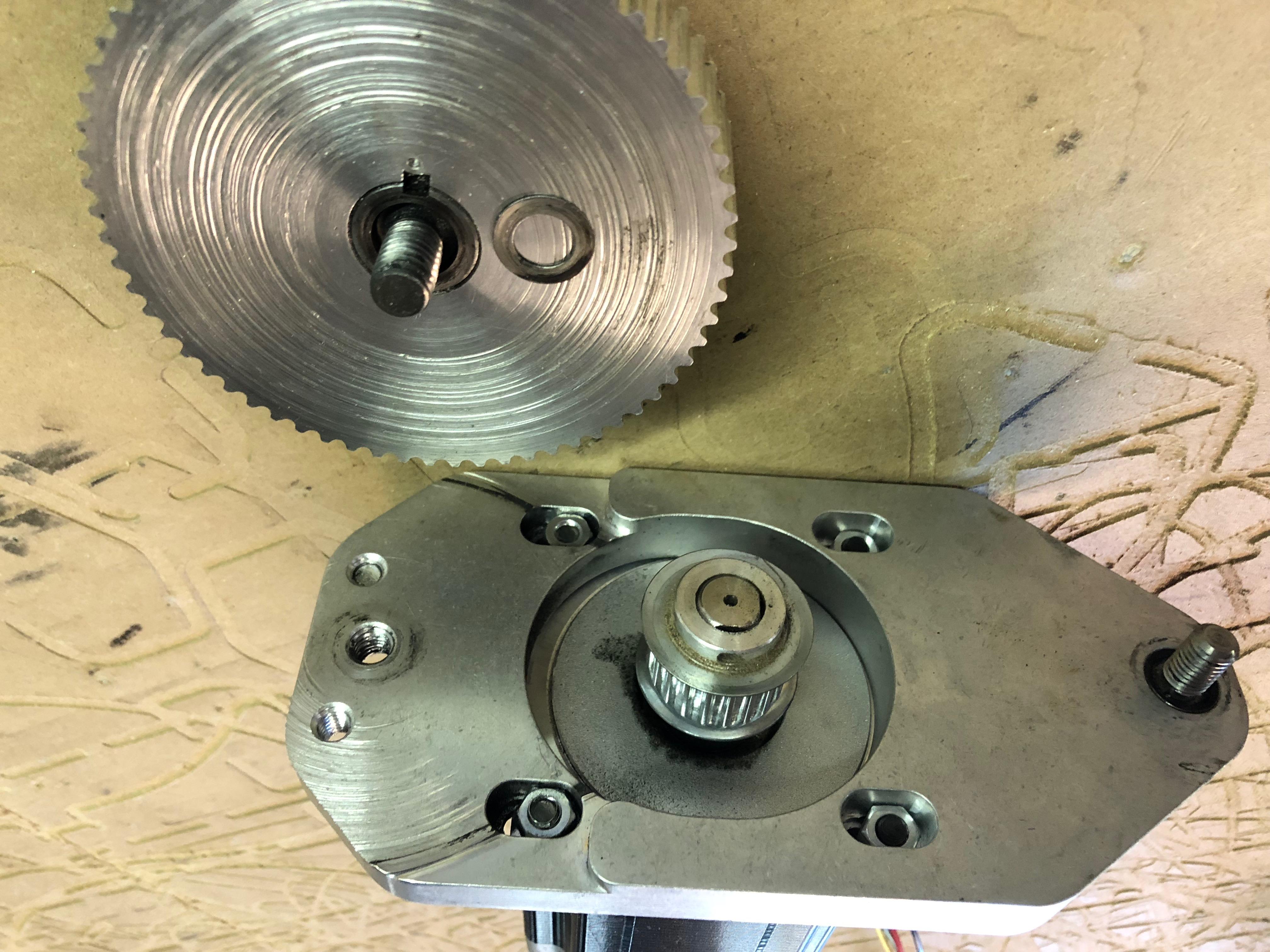

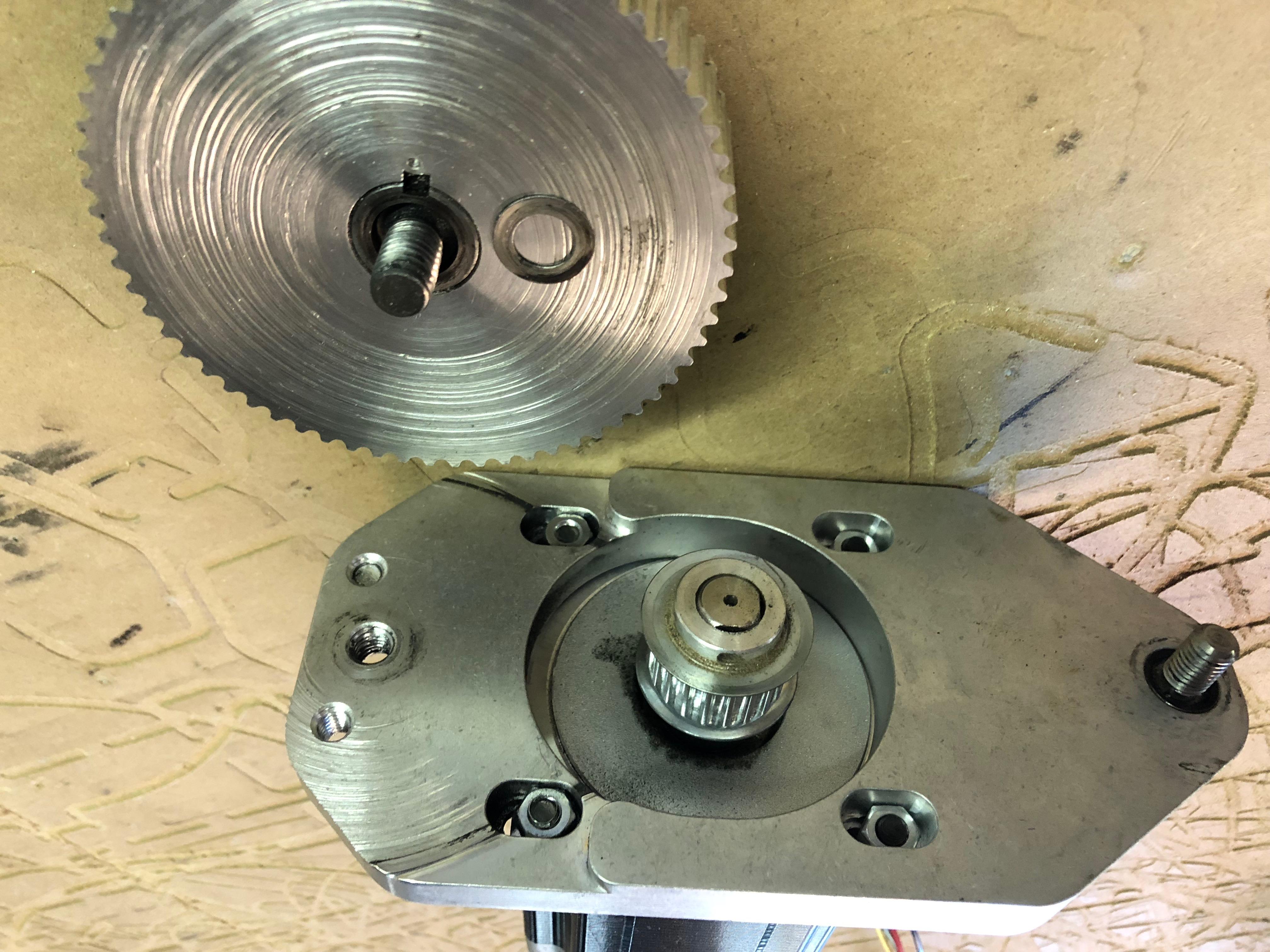

Today, I disassembled and measured the CNC Pinion bearing on the x-drive. The Pinion gear bearings are worn over 0.010 inch. As a result the pinion gear wobbles and rubs against the motor mounting plate. The worn bearing was without any lubrication. The shoulder bolt used for the axle is not worn, but shows discoloration from overheating.

The x-carriage pinion is worn enough to allow the pinion to wobble and grind against the center portion of the bridge. This wear will only get worse. The two y-drive pinions are also worn, but not badly enough to grind like the x. I reassembled the CNC Router, greasing the worn bearing and adding a polypropylene shim to reduce galling against the plate.

After reassembly, the CNC Router seems to be operating correctly, but my tests were limited in scope. If you have specific examples of problems please let me know the details.

Long term the solution is to replace the Pinion Gear bearings. Newer designs from CNCRouterparts.com show an integral super oilite bearing and matching ground shaft. This coupled with a thrust bearing between pinion and motor plate would eliminate the current wobble and grinding as well as reduce the potential for wear. The pinion kit is $49.75. We would need three to service all three drives.

CNCRouterparts has a complete kit which includes an upgraded motor plate and pinion for $164.50 x 3 = $493.5

I don’t think we need to spend the money to replace the whole assembly as the plate and motor pivot bearing are in good shape.

There are certainly others with longer experience on the CNC router than me. What do you’all think?

Dave

- well said!

- well said!