I fixed the CNC so the E-stops actually stop the thing. I checked the wiring and it seemed to be correct. I dug into the different config versions and apparently someone had shifted the Emergency circuit from Port 1 to Port 2 (effectively disabling it) and the Active Low setting was checked (which meant Emergency condition when buttons were up). I created a new config file with today’s date. Everything else is the same. I wonder if the E-stops were “disabled” when we were having erratic shutdowns due to noise on the E-stop circuit. I find this general disregard for safe operation disconcerting. At a bare minimum it should have been documented with a “why it was done”. Having E-stops that don’t do anything is worse than not having E-stops at all. They should also be moved away from the back of the machine to a more accessible location, like the front. I can try to do that next time I’m down there but I think the cabling is too short.

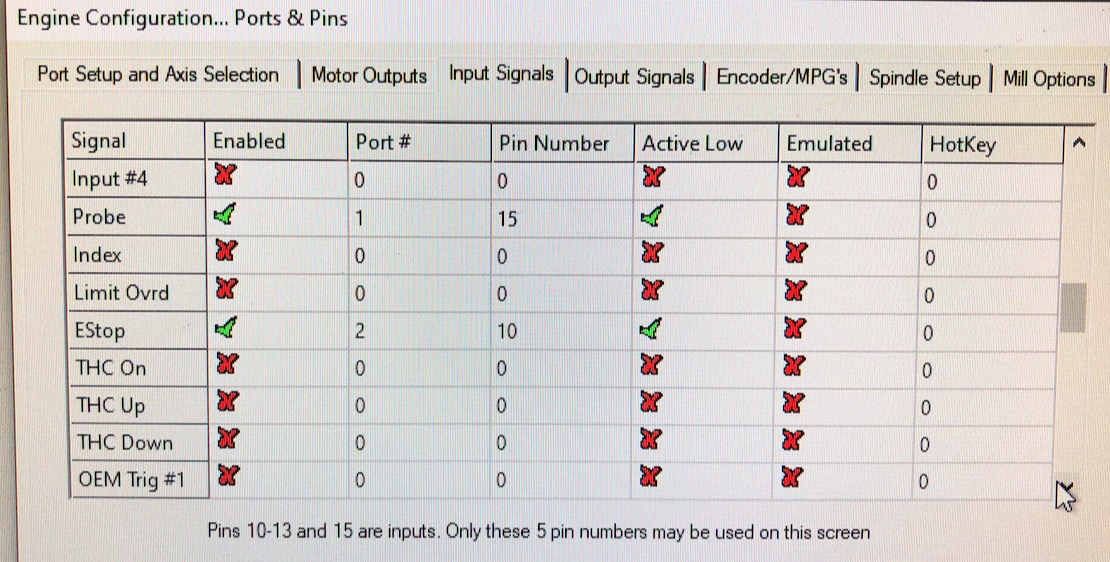

The incorrect setup:

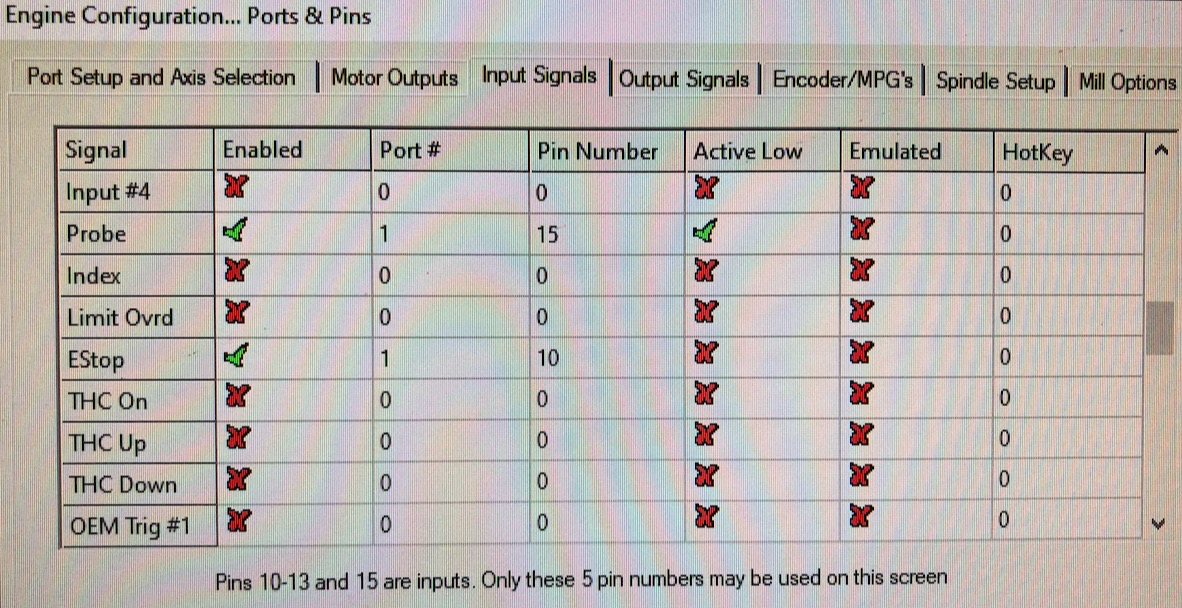

The correct setup

All the homing operations work (X, Y, Z) but the soft limits are not correctly setup. Basically you can drive the Y into the hard stop in the back and the X can just go right off the end of the gantry. Not the best setup. I ran out of time to fix that.

If you think this move ties up our time, wait until someone is seriously injured because safety systems were bypassed. The waiver doesn’t mean total protection in a case of negligence. You could get to be interviewed by government officials and potentially a lawyer because someone sued us for loss of limb.

Thanks,

Brad “happy its working” Walsh