Status Update

As you probably already know, the big laser was damaged in a fire on August 12th. This is an update on the repair status.

My personal target for completing repairs is 9/30/19. With your help we can get the Big Laser back in action this month.

Please let me know if you can help on these tasks by responding to this post. Several of you have already signed on to help, now we just need to get this done.

The enclosure has been cleaned. Thanks to everyone who helped.

Replacement parts have been ordered. $2000 was budgeted. $1060 has been spent so far. As tests proceed we may find something to replace, including the controller. (another story)

As of 9/11/19, 90% of the parts needed to reassemble the laser have arrived. The rest should arrive by 9/19/19. There is much we can do to get the big laser back up while waiting on the parts to arrive.

To Do Tasks:

Clean 30 bed bars - Anyone can do it. You will get dirty. You don’t have to wait on Saturday to do it either! WooHoo!

Make adapter bezel for mAmmeter - Laser cut on small laser or 3D print. We need this by 9/14 if possible.

Things we can do on Saturday 9/14 before the last parts arrive. We have all the parts required:

Test Power Supplies, stepper drivers, stepper motors and limit switches.

Install and wire in mAmmeter, eStop Switch, hour meter and key power switch. We need to build a new wire harness.

Install Leetro Controller and LaserCut2017

Test fire old laser tube without mirrors installed

Install LED strip under X gantry

Drain the chiller and cooling lines. Flush out the tank, clean the coil and reinstall with clean distilled water.

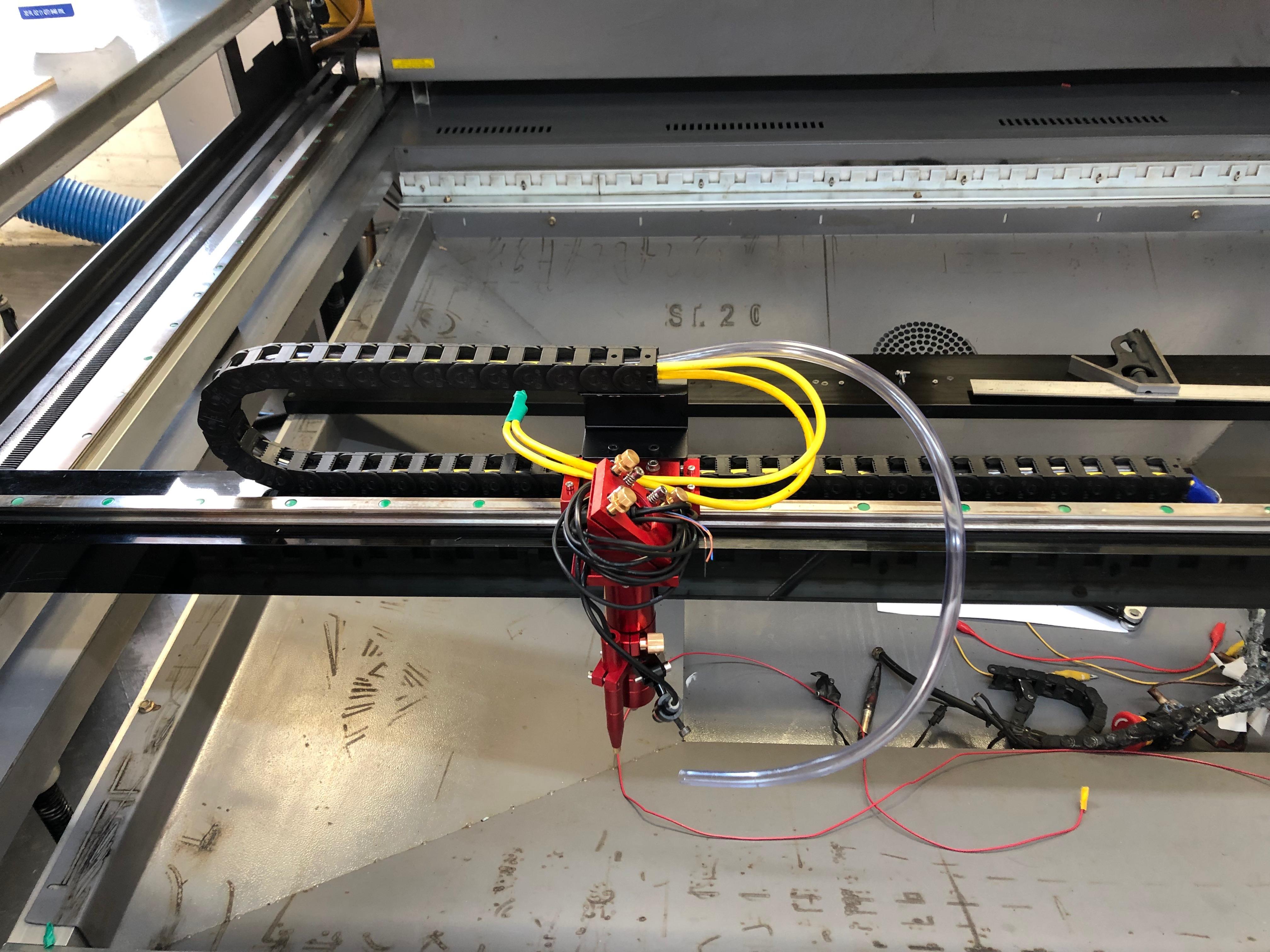

Install a new wire chain on the x gantry. Need to make or adapt some brackets.

Run new wiring for the Z-datum probe, the red dot aiming laser and air line to the laser head.

Tasks Waiting on parts:

Install z-datum probe on laser head. (waiting on probe)

Install x-axis slider and mount laser head (waiting on slider)

Install 1st and 2nd mirror mounts and mirrors - This must happen after x slider is installed.

Install belts on X and Y drives (waiting on belts)

Align Laser - this task needs two people to go faster

Test cuts

Tasks to do after the laser is up and running.

Install replacement lid struts

Install Ruida Controller

Document LightBurn use

Train Members on new updates to Laser Cutter