We have a bandsaw problem… Hive13 members have been slaughtering the bandsaw blades we bought. I just ordered some more, but to try and curb the damage rate, please everyone who chooses to use the bandsaw read/watch below.

it is 100% ESSENTIAL that EVERY time a bandsaw blade is changed, the entire saw must be readjusted. if you use the saw without verifying it is adjusted IT WILL RUIN THE BLADE.

the following video does a good job of quickly explaining the process:

https://www.youtube.com/watch?v=LE9IrZGs3SM

while I take exception to his claims of 3 TPI being good for everything (I would argue for any thin material you need at least 2 whole teeth to fall within the thickness of the material being cut) and his method for aligning the fence, the rest of the video is spot on.

A few key points that are easy to overlook, but very important:

- There are two sets of guides, one above the table that you can walk up and see, one below the table that is just as important.

- BEFORE putting the blade on, pull the guid blocks and thrust bearings back on both upper and lower guides. if you do not do this, pulling the blade through those guide blocks will squish the teeth removing the blade’s set and making it trash. without tooth set bandsaw blades cannot cut, they just burn

- Adjust the tracking of the blade turning the wheels by hand. Only power on the saw once they are tracking in place by hand and without the guid blocks.bearings touching the blade. Only power the saw on long enough to see the tracking is good under power, do not attempt to make a cut until the guides and bearings are adjusted.

- The guide blocks should support the blade BEHIND the tooth gullets. If the guide blocks touch the tooth, even in the gullet, it will ruin the blade. the guide blocks must also have just enough clearance to allow the blade to pass through without binding at the weld in the blade. Remember that both UPPER and LOWER pairs of guide blocks must be adjusted

- The upper and lower thrust bearings should be brought up just behind where the blade tracks on the wheels. they should not turn while the saw is not loaded except maybe a quick jump once or twice per rotation (typically at the weld). The bearings will turn when the blade is loaded by a workpiece, but should not when the blade is running free

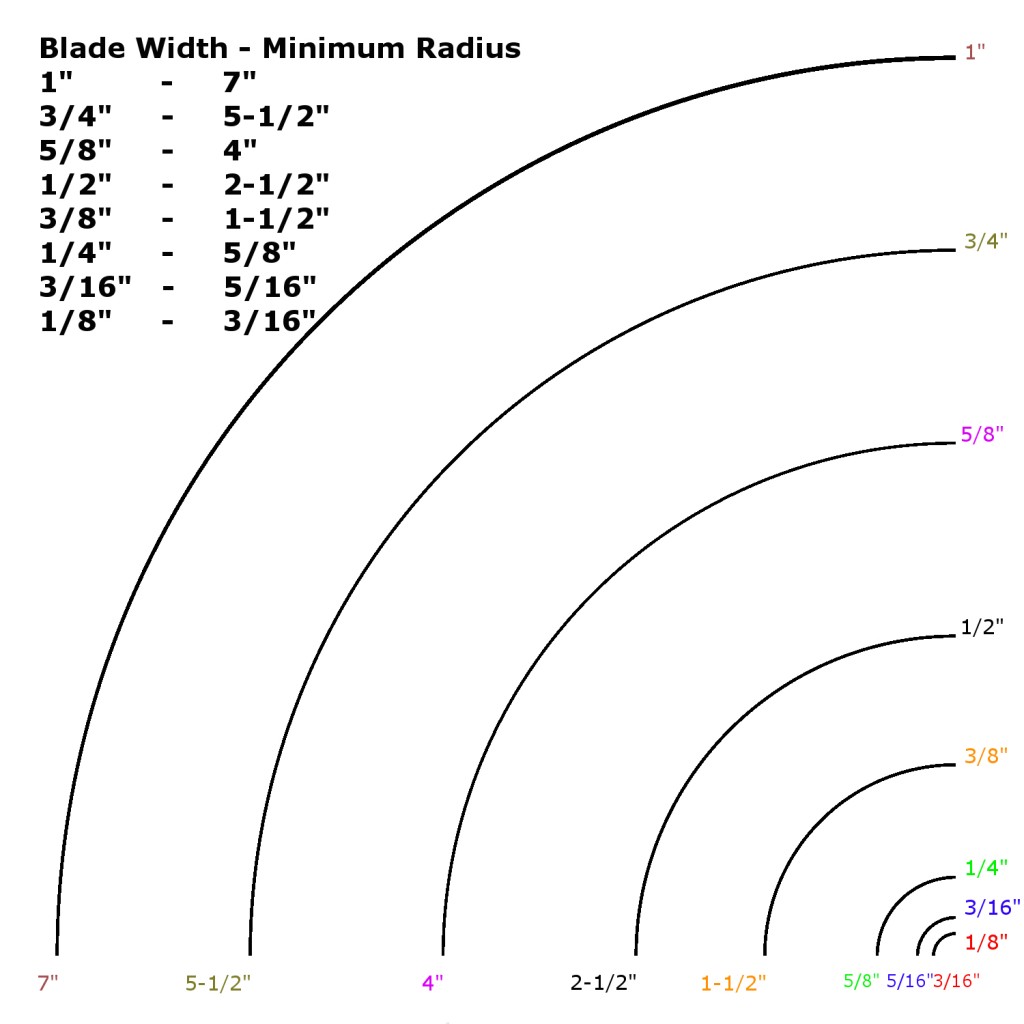

An additional point not covered in the video is that different blades have different purposes. DO NOT CUT CURVES WITH THE THICK BLADE (5/8" or 3/4"). It is for straight line cuts and resawing. Here is a handy chart for what thickness blades can be used for cutting what curves:

Because we have lots of members who use the bandsaw for quick walk-up cuts, please make sure the 1/4" blade is the one that stays on the saw. If you need to use another blade to do fine scroll work or resaw, CHANGE IT BACK WHEN DONE. the 1/4" x 6 TPI blades we have are good general purpose blades for 90% of what our bandsaw gets used for at Hive13. Thus, It should be the one to stay on the saw.

It is every member’s responsibility to make sure the bandsaw is adjusted before using it, even if you are not the one who changed the blade. If anyone needs an in-person demo to make sure you have the process down, please don’t hesitate to ask for help. I have warden hours tomorrow evening or can meet you whenever is convenient.

Thanks,

Kevin McLeod

Woodworking Warden